In the ever – evolving packaging industry, battery contacts have emerged as essential yet often overlooked components that contribute significantly to the functionality and innovation of various packaging solutions. These seemingly simple elements act as the vital link between batteries and the electrical systems integrated into packaging, enabling features such as smart monitoring, interactive displays, and automated functions. From packaging for consumer goods to pharmaceutical and industrial products, battery contacts play a crucial role in enhancing product protection, user experience, and supply chain efficiency. Let’s explore the diverse applications and significance of battery contacts in the packaging industry.

1.The Core Function of Battery Contacts in Packaging Applications

Battery contacts serve as the fundamental connection for powering the electrical components within packaging. Their primary role is to establish a stable and reliable electrical pathway between the battery and various devices integrated into the packaging, such as sensors, LED indicators, or small – scale processors. For example, in temperature – sensitive pharmaceutical packaging, battery contacts power the temperature sensors that continuously monitor the internal environment. By ensuring a consistent flow of electricity, these contacts prevent data loss or inaccurate readings that could compromise the integrity of the products. In smart packaging for consumer electronics, battery contacts enable interactive features like touch – sensitive displays or augmented reality experiences, enhancing the overall user engagement with the product and its packaging.

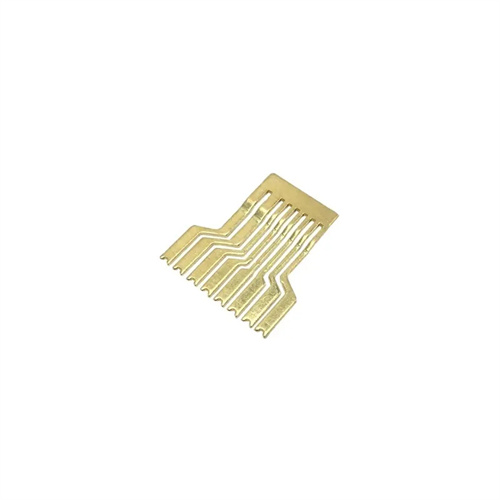

2.Materials and Durability Requirements for Battery Contacts in Packaging

Given the diverse and often challenging environments that packaging materials encounter, the materials used for battery contacts must meet strict durability and performance standards. We prioritize materials with excellent electrical conductivity, corrosion resistance, and mechanical strength. Stainless steel is a popular choice due to its ability to withstand exposure to moisture, chemicals, and varying temperatures during transportation and storage. Brass and phosphor bronze are also commonly employed for their superior electrical properties and spring – like characteristics, which ensure a secure connection with the battery even under vibrations or mechanical stress. Additionally, in food and pharmaceutical packaging, where hygiene is of utmost importance, the materials used for battery contacts must be non – toxic and compliant with relevant safety regulations, such as FDA guidelines in the United States or EU food safety standards.

3.Design Considerations for Battery Contacts in Packaging Solutions

Designing battery contacts for packaging requires a careful balance of functionality, compactness, and ease of integration. The shape and size of the contacts must be precisely tailored to fit within the limited space of the packaging while maintaining a secure connection with the battery. In minimalist packaging designs, where every millimeter of space matters, highly miniaturized and efficient contact designs are essential. We often incorporate features like snap – on or press – fit mechanisms to simplify battery installation and replacement, especially for consumer – facing packaging. Moreover, the design of battery contacts also takes into account the need for protection against accidental disconnections or short circuits. For instance, in packaging for electronic devices, insulating materials are used around the contacts to prevent any electrical interference that could damage the product or pose a safety risk to users.

4.Diverse Applications of Battery Contacts in the Packaging Industry

Battery contacts find widespread use across various segments of the packaging industry. In the food and beverage sector, they power freshness indicators and RFID tags integrated into packaging, allowing consumers and retailers to monitor the product’s quality and track its movement in the supply chain. For luxury goods, battery contacts enable the creation of elegant and interactive packaging experiences, such as illuminated logos or hidden compartments that open with the touch of a button. In the industrial packaging of heavy machinery parts, battery contacts are used to power sensors that detect any damage or movement during transit, providing valuable data for quality control and logistics management. These diverse applications highlight the versatility of battery contacts in transforming traditional packaging into smart, functional, and user – centric solutions.

5.Future Trends and Innovations of Battery Contacts in Packaging

As the packaging industry continues to embrace digitalization and sustainability, battery contacts are set to undergo significant advancements. The future will see an increased integration of battery – powered smart sensors and IoT devices into packaging, which will require more sophisticated and reliable battery contacts. We anticipate the development of self – healing contacts that can repair minor damages caused by environmental factors, ensuring a longer lifespan for the packaging’s electrical components. Additionally, with the growing focus on sustainable packaging, there will be a push to develop battery contacts made from recyclable or biodegradable materials. The advent of wireless charging technology may also revolutionize packaging design, allowing for the elimination of traditional battery contacts in some applications and enabling more seamless and aesthetically pleasing packaging solutions.