In the rapidly evolving landscape of LED lighting, terminal connectors serve as the essential links that enable the seamless flow of electrical power and data, ensuring the reliable operation of various lighting systems. From the smallest LED bulbs to large – scale commercial lighting installations, these connectors play a pivotal role in establishing secure electrical connections, facilitating easy installation, and enhancing the overall performance and longevity of LED lighting products. Whether we are involved in the manufacturing, installation, or maintenance of LED lighting, terminal connectors are indispensable components that we rely on to deliver high – quality, energy – efficient lighting solutions.

1.Terminal Connectors in LED Bulb and Tube Assembly

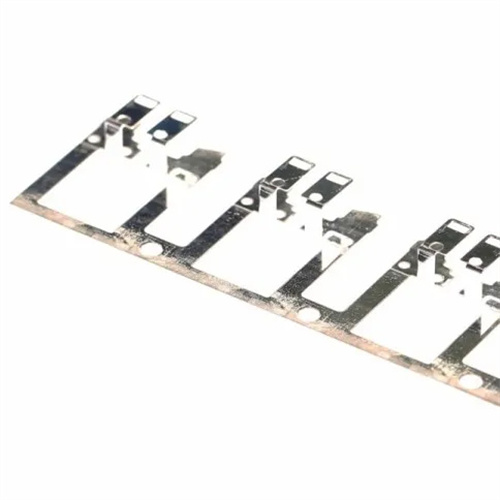

When we assemble LED bulbs and tubes, terminal connectors are crucial for establishing the electrical connection between the LED light source and the power supply. These connectors are designed to provide a stable and reliable link, ensuring that the LED receives the correct voltage and current for optimal performance. In LED bulbs, we typically use screw – type or push – in terminal connectors to connect the wires from the power source to the bulb’s internal circuitry. The screw – type connectors offer a secure hold, allowing us to tighten the wires firmly in place, while push – in connectors provide a quick and convenient installation option. In LED tubes, terminal connectors are often integrated into the end caps, enabling easy connection to the fixtures. These connectors must be able to withstand the heat generated by the LED, as well as the mechanical stresses during installation and handling, to ensure long – term reliability.

2.Terminal Connectors in LED Strip Light Installations

LED strip lights are widely used for various decorative and functional lighting applications, and terminal connectors are essential for their installation. We use different types of terminal connectors to connect the LED strips to the power supply, as well as to join multiple strips together to create longer lighting runs. One common type is the snap – on terminal connector, which allows us to easily insert the stripped ends of the wires into the connector and secure them with a snap – in mechanism. This type of connector provides a secure and insulated connection, preventing short circuits and ensuring the safety of the installation. For longer LED strip light installations, we may use inline terminal connectors to join multiple strips end – to – end. These connectors ensure a seamless electrical connection, allowing the light to flow continuously along the entire strip.

3.Terminal Connectors in LED Panel Lighting Systems

In LED panel lighting systems, which are commonly used in commercial and residential settings for general illumination, terminal connectors play a vital role in the assembly and installation process. We use terminal connectors to connect the individual LED panels to the power distribution system, as well as to link the panels together to create larger lighting arrays. These connectors need to be able to handle high currents and provide a low – resistance path for the electrical power to ensure efficient operation of the panels. Some advanced LED panel lighting systems use plug – and – play terminal connectors, which simplify the installation process and reduce the risk of installation errors. These connectors also allow for easy maintenance and replacement of individual panels, as we can simply unplug and replace a faulty panel without having to rewire the entire system.

4.Terminal Connectors in Outdoor LED Lighting Applications

Outdoor LED lighting applications, such as streetlights, landscape lighting, and sign lighting, are exposed to harsh environmental conditions, and terminal connectors need to be designed to withstand these challenges. We use weatherproof and waterproof terminal connectors in outdoor LED lighting to prevent moisture, dust, and other contaminants from entering the electrical connections. These connectors are typically made of durable materials, such as high – quality plastics and metals, and are equipped with seals and gaskets to ensure a tight and secure fit. In addition, outdoor terminal connectors need to be able to withstand temperature fluctuations, UV radiation, and mechanical stresses. By using reliable terminal connectors in outdoor LED lighting, we can ensure the long – term performance and reliability of the lighting system, even in the most demanding environments.

5.Future Trends and Innovations in Terminal Connectors for LED Lighting

As the LED lighting industry continues to evolve, the demand for more advanced and efficient terminal connectors is increasing. We can expect to see the development of new terminal connector technologies that offer improved electrical performance, such as lower contact resistance and higher current – carrying capacity. Additionally, there will be a growing focus on miniaturization and integration of terminal connectors, as LED lighting products become smaller and more compact. The use of smart terminal connectors with built – in sensors and communication capabilities is also likely to become more prevalent, enabling features such as remote monitoring, fault detection, and automatic adjustment of the lighting system. Furthermore, with the increasing emphasis on sustainability, there will be a trend towards using more eco – friendly materials in the manufacturing of terminal connectors for LED lighting. These future trends and innovations will not only enhance the performance and functionality of LED lighting but also contribute to the development of more intelligent and sustainable lighting solutions.