Battery contact plates are important components used in batteries to connect internal and external circuits. Their main function is to transmit current and ensure normal charging and discharging of the battery.

Battery contact plates are usually made of metals with good conductivity, such as copper, nickel, silver, etc. These metals have good conductivity and corrosion resistance, ensuring stable current transmission and extending the service life of batteries.

The design and manufacturing quality of Battery Contact Plates have a significant impact on the performance and safety of batteries. They need to have good elasticity and durability to adapt to the deformation and vibration of the battery during use. At the same time, Battery Contact Plates also need to have certain corrosion and oxidation resistance to ensure stable performance under various environmental conditions.

MCB Connector Terminal (MCB Connector Terminal) is an important component in electrical system for connecting MCB and circuit conductor.

1、 Definition and Function

MCB Connector Terminal is a terminal block designed for MCB, which provides a separable interface between MCB and circuit conductor. This connector ensures a safe and reliable connection of the circuit and allows easy disconnection of the circuit when required. Flexible circuit configuration and fast maintenance can be realized through MCB Connector Terminal.

2、 Materials and Properties

Material: MCB Connector Terminal is usually made of metal with good conductivity, such as brass. These materials have good conductivity, corrosion resistance and mechanical strength and can meet the requirements of electrical connection.

Characteristics:

Good conductivity: ensure smooth current transmission in the circuit and reduce resistance and energy loss.

Strong corrosion resistance: it can resist the humidity, salt mist and other corrosive factors in the environment and extend the service life.

Safety and reliability: reasonable design, compact structure, safe and reliable circuit connection.

Easy installation and maintenance: convenient for users to connect, disconnect and check.

3、 Scope of application

MCB Connector Terminal is widely used in various low-voltage electrical systems, especially in the occasions where frequent circuit breaking and circuit making are required. They are used in residential, commercial and industrial buildings such as switchboards, control panels and motor control centers. In industrial electrical equipment, miniature circuit breaker is used to connect various machines and equipment to ensure stable power supply during production. In the distribution box of commercial building, connect the miniature circuit breaker of different circuits with wires to realize reasonable power distribution and control. In the smart home system, as the key component of power connection, it ensures the safe operation of smart appliances.

In the power distribution system of a large shopping mall, MCB Connector Terminal is reliably connected with the miniature circuit breaker in each area, so that the power can be stably supplied to lighting, air conditioning and other equipment; In the production line of an automatic plant, it provides reliable connection for miniature circuit breaker of key equipment and ensures the continuity of production.

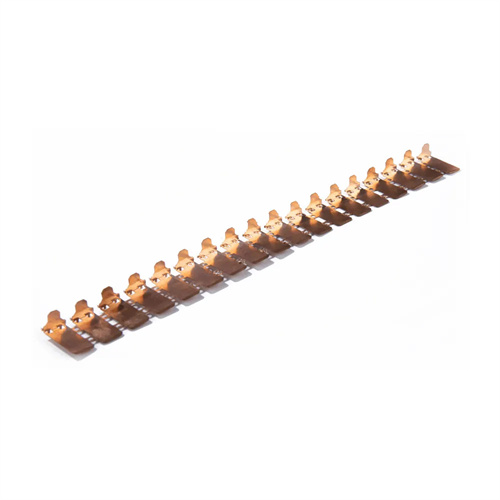

Metal Battery Contact Springs feature the following:

Excellent conductivity: made of metal, usually copper, silver or its alloy, which can conduct current efficiently and reduce energy loss caused by resistance.

Excellent elastic recovery capacity: it can withstand frequent compression and expansion during the use of the battery, and always maintain the pressure on the battery electrode to ensure stable contact.

Corrosion resistance: resist the corrosion of chemical substances inside the battery and maintain stable performance in harsh chemical environment.

High-precision size and shape: it is precisely machined and perfectly matched with the contact part of the battery to ensure the reliability and consistency of contact.

High fatigue strength: it can withstand repeated deformation for a long time without failure, and extend the service life of the battery.

In practical applications, such as in batteries of portable electronic equipment (such as mobile phones and tablet computers), Metal Battery Contact Springs ensures stable power supply of the equipment under various use conditions; In the power battery pack of electric vehicles, they provide reliable connection for the transmission of large current. In addition, Metal Battery Contact Springs of different types and specifications will be customized according to specific battery requirements to meet different operating voltage, current and installation space requirements.

Metal battery contact springs, also known as battery shrapnel or battery connection clips, are an electronic hardware material, usually made of metal materials such as spring steel, stainless steel, copper, etc. These materials have good electrical conductivity, elasticity and corrosion resistance, which ensures the stable connection of the battery contact spring in the battery or circuit and the reliability of the electrical performance.

The main function of the battery contact spring is to fix and support the battery, and establish a circuit connection with the battery. In the production process, metallic or non-metallic materials are cold-stamped into parts or semi-finished products by stamping dies, a special process that ensures the precision and durability of the contact springs.

According to specific application scenarios and needs, metal battery contact springs can be divided into various types. For example, steel battery contact springs have high strength and elastic modulus, which can withstand certain extrusion and tensile forces, so they are widely used in high-volume production of electrical appliances. Copper battery contact springs, on the other hand, are often used in electrical appliances that require frequent battery replacement due to their good conductivity and corrosion resistance.

Note that the environment in which the metal battery contact spring is applied is also an important factor to consider. In salt spray environments, high and low temperature environments, or humid environments, metal battery contact springs may be subject to corrosion or failure. Therefore, when selecting and applying battery contact springs, it is necessary to consider comprehensively according to the actual use environment.