In the intricate and diverse world of electrical products, terminal connectors serve as the unsung heroes that enable the seamless connection of electrical components, ensuring the reliable operation and functionality of everything from the simplest household appliances to the most complex industrial machinery. These connectors act as the essential links in electrical circuits, facilitating the transfer of electrical power and signals while providing mechanical support and protection. Whether we are manufacturing, installing, or maintaining electrical products, terminal connectors are indispensable components that we rely on to build robust, efficient, and safe electrical systems.

1.Terminal Connectors in Electrical Panel Assembly

When we assemble electrical panels, which are the nerve centers of many electrical systems, terminal connectors play a crucial role. In these panels, we use various types of terminal connectors to connect wires, cables, and electrical components such as circuit breakers, switches, and relays. Screw – type terminal connectors are commonly employed, as they allow us to firmly secure the wires in place by tightening the screws. This ensures a stable electrical connection that can withstand the electrical currents and mechanical stresses encountered in the panel. Additionally, busbar terminal connectors are used to connect multiple wires or components to a common electrical bus, enabling efficient power distribution. The proper selection and installation of terminal connectors in electrical panels are essential for preventing electrical failures, ensuring safety, and facilitating easy maintenance.

2.Terminal Connectors in Power Distribution Equipment

Power distribution equipment, such as transformers, switchgear, and power distribution boxes, also heavily rely on terminal connectors. In transformers, terminal connectors are used to connect the primary and secondary windings to the electrical network. These connectors must be able to handle high voltages and currents while maintaining a low – resistance connection to minimize power losses. In switchgear, terminal connectors are used to connect the incoming and outgoing power cables, as well as to link the various switching and protective devices. Quick – connect terminal connectors are often preferred in some applications due to their ease of installation and removal, which is beneficial for maintenance and troubleshooting. By using reliable terminal connectors in power distribution equipment, we can ensure the efficient and safe delivery of electrical power to different parts of a building or an industrial facility.

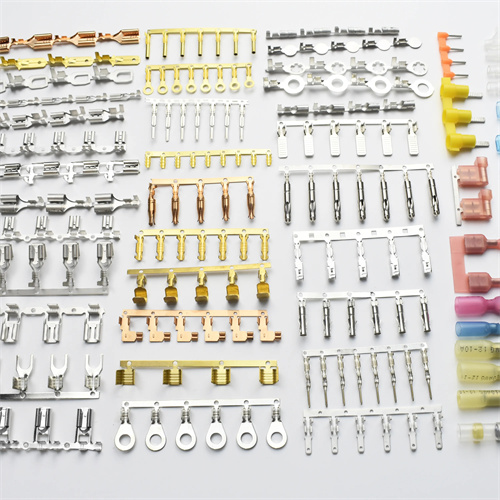

3.Terminal Connectors in Electronic Devices

In electronic devices, from smartphones and laptops to advanced medical equipment and industrial control systems, terminal connectors are vital for connecting the internal components. Printed circuit board (PCB) terminal connectors are used to connect external wires or cables to the PCB, allowing for the transfer of electrical signals and power. These connectors come in various forms, such as pin headers, socket connectors, and edge connectors. For example, in a laptop, pin header terminal connectors are used to connect the battery, keyboard, and other peripheral devices to the main PCB. In addition, ribbon cable terminal connectors are commonly used to connect flexible printed circuits, enabling compact and reliable connections in space – constrained electronic devices. The performance and reliability of terminal connectors in electronic devices directly impact the overall functionality and lifespan of the devices.

4.Terminal Connectors in Electrical Wiring and Cabling

Electrical wiring and cabling are the lifelines of electrical systems, and terminal connectors are essential for joining and terminating wires. When we install electrical wiring in buildings or run cables in industrial settings, we use wire nuts, crimp connectors, and terminal blocks. Wire nuts are simple yet effective terminal connectors used to join multiple wires together. They provide a secure and insulated connection, preventing electrical shorts and ensuring the safety of the electrical system. Crimp connectors, on the other hand, are used to permanently attach wires to terminals or connectors by deforming the connector around the wire using a crimping tool. Terminal blocks are widely used in electrical panels and control cabinets to organize and connect multiple wires. They offer a convenient way to make and break electrical connections, facilitating wiring installation, modification, and maintenance.

5.Future Trends and Innovations in Terminal Connectors for Electrical Products

As the electrical product industry continues to evolve with the advancement of technology, the demand for more advanced terminal connectors is increasing. We can expect to see the development of terminal connectors with enhanced electrical performance, such as lower contact resistance and higher current – carrying capacity. Miniaturization will also be a key trend, as electrical products become smaller and more compact. Additionally, the integration of smart features into terminal connectors, such as self – monitoring and self – healing capabilities, is likely to become more prevalent. These smart terminal connectors will be able to detect and report faults, adjust their connections automatically, and even communicate with other components in the electrical system. Moreover, the use of environmentally friendly materials in the manufacturing of terminal connectors will gain more importance as the industry moves towards sustainability. These future trends and innovations will further enhance the performance, reliability, and functionality of electrical products.