The Fundamental Design of Durable Battery Contacts

Our Consumer Electronics Battery Contacts are built upon the fundamental design of durable pogo pins and spring – loaded mechanisms. Pogo pins, with their slender and precise structure, are designed to establish a reliable electrical connection between the battery and the device. The spring – loaded design within these contacts is crucial, as it allows for automatic adjustment to variations in the distance between the battery terminals and the contact points on the device.

When the battery is inserted, the spring within the pogo pin compresses, applying a consistent and firm pressure. This pressure ensures that the contact surface remains in close and continuous contact with the battery terminal, minimizing electrical resistance. The design also enables easy insertion and removal of the battery, making it user – friendly while maintaining a secure connection, which is essential for the smooth operation of consumer electronics.

Advantages of Pogo Pins in Battery Contacts

Pogo pins offer numerous advantages in our Consumer Electronics Battery Contacts. Firstly, their small size and compact design make them ideal for the increasingly slim and space – constrained consumer electronics devices, such as smartphones and wearable gadgets. Despite their tiny form, pogo pins can handle a significant amount of electrical current, ensuring efficient power transfer.

Secondly, pogo pins are highly durable. The spring – loaded mechanism can withstand repeated insertion and removal cycles without losing its elasticity or performance. The pins themselves are made from high – quality materials, often with a plating to enhance conductivity and corrosion resistance. This durability ensures that the battery contacts maintain a stable connection over the long – term use of the device, reducing the risk of intermittent power supply or connection failures.

The Role of Spring Loaded Designs in Battery Contacts

Spring – loaded designs play a pivotal role in our Consumer Electronics Battery Contacts. The spring within the contact acts as a shock absorber, compensating for any movement or vibrations that the device might experience during use. This is particularly important in mobile devices that are constantly on the move, as it prevents the contacts from losing connection due to jolts or shakes.

Moreover, the spring – loaded design allows for a more consistent clamping force. It ensures that the contact pressure remains constant, regardless of factors such as temperature changes or minor wear and tear on the battery or device terminals. This consistency is key to maintaining a reliable electrical connection, which in turn contributes to the overall performance and battery life of the consumer electronics product.

Meticulous Manufacturing Process of Battery Contacts

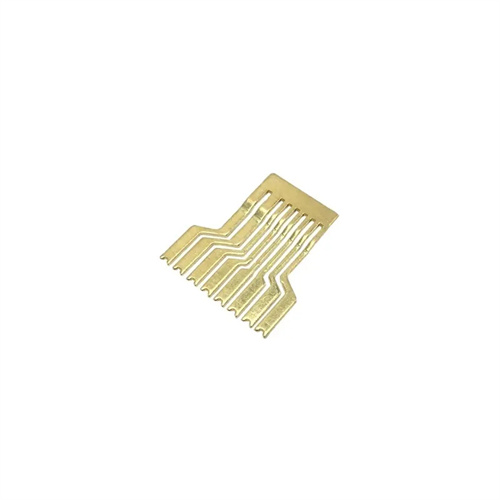

The production of our Consumer Electronics Battery Contacts involves a meticulous manufacturing process. We begin by sourcing top – grade materials for the pogo pins and springs, ensuring high conductivity, durability, and corrosion resistance. The pogo pins are precision – machined using advanced stamping or turning techniques to achieve the exact dimensions required for a perfect fit.

After machining, the pins undergo a series of surface treatments, such as plating with materials like gold or nickel to enhance their electrical properties. The springs are carefully formed and heat – treated to optimize their elasticity and fatigue resistance. Each contact is then assembled with precision, and rigorous quality control checks are carried out. We test for electrical conductivity, contact force, and durability through simulated insertion and removal cycles, ensuring that only the highest – quality battery contacts reach our customers.

Diverse Applications of Battery Contacts in Consumer Electronics

Our Consumer Electronics Battery Contacts with durable pogo pins and spring – loaded designs find diverse applications across the consumer electronics landscape. In smartphones, they are used to connect the battery to the mainboard, ensuring a stable power supply for all the device’s functions, from calling and texting to running power – intensive apps and games.

For tablets and laptops, these contacts enable efficient charging and power transfer, supporting long – hours of work and entertainment. Wearable devices, such as smartwatches and fitness trackers, also rely on our battery contacts. Their compact and durable nature is perfect for the small – scale, high – usage environment of wearables. Additionally, in wireless earbuds and other portable audio devices, our battery contacts ensure a reliable connection for continuous playback.

Comprehensive Customer Support for Battery Contacts

We are committed to providing comprehensive customer support for our Consumer Electronics Battery Contacts. Our team of experts is available to assist customers throughout the entire process, from product selection to after – sales service. We offer detailed technical advice on choosing the right type of contact for different consumer electronics products, taking into account factors such as battery size, power requirements, and device design.

In case of any issues or concerns, our responsive after – sales service team is ready to provide prompt solutions. Whether it’s a question about product performance, a need for replacement parts, or assistance with installation, we strive to ensure that our customers are completely satisfied with our products and services. We also welcome feedback from our customers to continuously improve our offerings, aiming to build long – term relationships based on trust, reliability, and exceptional support in the consumer electronics industry.