Material Synergy in High-Conductivity Battery Contacts

Our High-Conductivity Battery Contacts leverage the powerful synergy of copper and nickel plating to achieve optimal performance. Copper, renowned for its exceptional electrical conductivity, forms the core of these contacts. Its atomic structure allows electrons to flow freely, minimizing resistance and enabling efficient power transfer. When combined with nickel plating, the material’s capabilities are further enhanced.

Nickel, with its own good conductivity properties, adds an extra layer of functionality. It provides a smooth and stable surface for electrical contact, reducing the risk of arcing and wear. Moreover, nickel plating acts as a protective barrier, preventing the underlying copper from oxidation and corrosion. This combination of copper’s conductivity and nickel’s protective and conductive qualities creates Battery Contacts that are not only highly efficient but also durable, ensuring long-term reliable performance in various battery-powered applications.

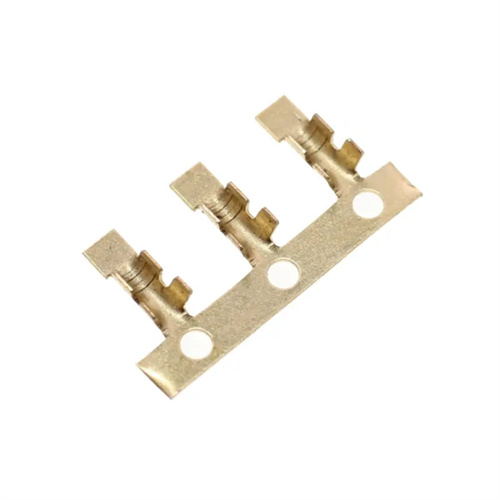

Design Principles of High-Conductivity Battery Contacts

The design of our High-Conductivity Battery Contacts is based on principles that prioritize both conductivity and stability. We optimize the shape and size of the contacts to maximize the contact area with battery terminals. A larger contact area means lower contact resistance, facilitating a seamless flow of electrical current. The surfaces of the contacts are carefully polished and refined to ensure a smooth interface, further reducing resistance.

In addition, the structure of the contacts is engineered to withstand mechanical stress. The spring-loaded or fixed designs are crafted to maintain consistent pressure on the battery terminals, ensuring a secure connection even under vibrations or movement. The precise placement of the copper/nickel plating is also a key design aspect, ensuring that the most critical contact areas receive the maximum benefit of the high-conductivity and protective properties of the materials, all while fitting seamlessly into various battery and device configurations.

Superior Performance of High-Conductivity Battery Contacts

Our High-Conductivity Battery Contacts deliver superior performance that sets them apart in the market. The low electrical resistance provided by the copper core and nickel plating results in minimal power loss during energy transfer. This efficiency is crucial, especially in high-drain applications where every bit of energy saved can extend the battery life of devices. Whether it’s a smartphone running power-intensive apps or a high-performance industrial tool, our contacts ensure that the battery’s power is utilized to its fullest potential.

Moreover, the durability of these contacts contributes to their outstanding performance. The nickel plating protects the copper from environmental factors that could degrade conductivity over time. This means that the contacts maintain their high-conductivity levels even after prolonged use, reducing the likelihood of connection failures and the need for frequent replacements. The combination of high conductivity and long-term reliability makes our Battery Contacts a top choice for manufacturers and end-users alike.

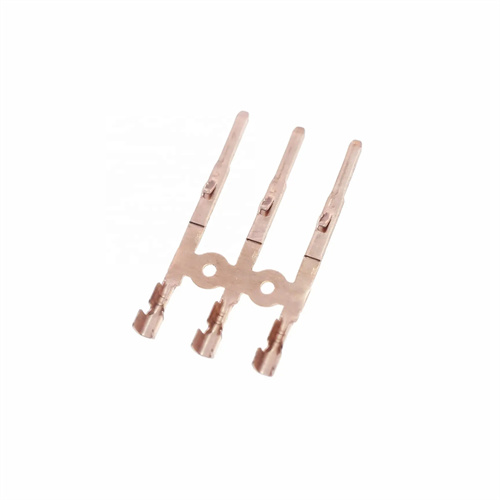

Meticulous Manufacturing Process of High-Conductivity Battery Contacts

The production of our High-Conductivity Battery Contacts involves a meticulous manufacturing process that adheres to the highest quality standards. We begin by sourcing premium-grade copper materials with precise chemical compositions to ensure optimal conductivity. The copper is then shaped into the desired contact forms using advanced stamping or machining techniques, with strict control over dimensions to ensure a perfect fit in battery applications.

After shaping, the contacts undergo the nickel plating process. We use advanced electroplating methods, carefully controlling parameters such as plating thickness, temperature, and current density to achieve an even and consistent nickel coating. Following plating, each contact is thoroughly inspected. We use advanced testing equipment to measure electrical conductivity, plating thickness, and surface quality. Only contacts that pass these rigorous tests are approved for distribution, guaranteeing that our customers receive Battery Contacts of the highest quality and performance.

Diverse Applications of High-Conductivity Battery Contacts

Our High-Conductivity Battery Contacts find diverse applications across multiple industries. In the consumer electronics sector, they are essential components in smartphones, laptops, tablets, and wearable devices, ensuring a stable and efficient power supply for seamless operation. The high conductivity allows for fast charging and reliable power delivery, enhancing the user experience.

In the automotive industry, especially in electric and hybrid vehicles, these contacts play a crucial role in connecting battery packs to the vehicle’s electrical systems. They can handle the high currents required for propulsion and other electrical functions, withstanding the vibrations and temperature fluctuations under the hood. Additionally, in industrial applications such as uninterruptible power supplies, energy storage systems, and manufacturing equipment, our Battery Contacts provide a reliable and efficient power connection, contributing to the overall productivity and reliability of these systems.

Comprehensive Customer Support for High-Conductivity Battery Contacts

We are committed to providing comprehensive customer support for our High-Conductivity Battery Contacts. Our team of experts is available to assist customers throughout the entire process, from the initial product selection to after-sales service. We offer detailed technical advice on choosing the right type of contact for specific applications, taking into account factors such as battery size, power requirements, and operating environment.

In case of any issues or concerns, our responsive after-sales service team is ready to provide prompt solutions. Whether it’s a question about product performance, a need for replacement parts, or assistance with installation, we strive to ensure that our customers are completely satisfied with our products and services. We also welcome feedback from our customers to continuously improve our offerings, aiming to build long-term relationships based on trust, reliability, and exceptional support in the battery contact market.