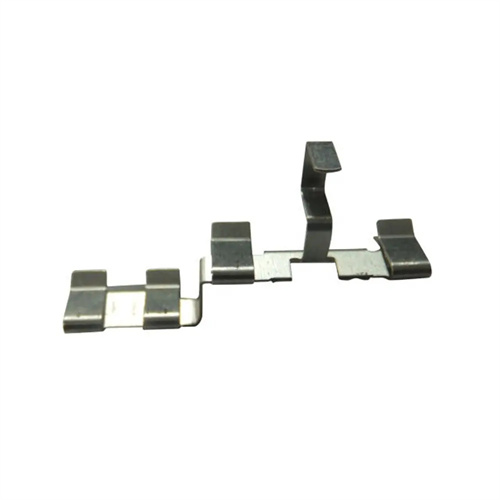

Unparalleled Advantages of Custom Electrical Contact Design

As providers of Custom Electrical Contact Design services, we offer unparalleled advantages to our clients. We recognize that one – size – fits – all solutions rarely meet the unique requirements of modern electrical systems. Our custom approach allows us to tailor electrical contacts precisely to the specific needs of each application, whether it’s for a niche consumer product or a complex industrial machinery.

Our ability to combine engineering expertise with advanced design tools sets us apart. We can optimize the electrical, mechanical, and thermal properties of the contacts, ensuring high – performance and reliability. Moreover, our in – house prototyping services enable rapid iterations and improvements, reducing the time and cost associated with bringing a new product to market. This comprehensive package of custom design, engineering support, and prototyping gives our clients a competitive edge in their respective industries.

Collaborative Design Process for Electrical Contacts

Our design process for Custom Electrical Contacts is highly collaborative. We start by engaging closely with our clients to understand their exact requirements, including electrical load, operating environment, space constraints, and performance expectations. Our team of experienced electrical and mechanical engineers works hand – in – hand with clients, using detailed discussions, site visits, and technical reviews to gather all necessary information.

Using state – of – the – art CAD software, we create initial design concepts that incorporate the client’s specifications. These concepts are then presented to the client for feedback. Through an iterative process of refinement and review, we ensure that the final design not only meets but exceeds the client’s expectations. This collaborative approach guarantees that the custom electrical contacts are perfectly aligned with the intended application and end – user needs.

In – Depth Engineering Support for Electrical Contacts

Our engineering support for Custom Electrical Contact Design goes beyond the initial design phase. We have a team of specialized engineers who provide in – depth analysis and technical guidance throughout the project. For electrical performance, we conduct simulations to optimize conductivity, minimize resistance, and prevent electrical arcing. In terms of mechanical design, we analyze factors such as stress distribution, fatigue life, and durability to ensure the contacts can withstand the expected mechanical loads.

We also offer support in material selection, recommending the most suitable materials based on the application’s requirements, such as high – conductivity metals for electrical contacts and durable polymers for insulation. Our engineers are available to answer any technical questions, address potential challenges, and provide innovative solutions, ensuring that the custom electrical contacts are engineered to the highest standards.

Efficient Prototyping Services for Electrical Contacts

Our prototyping services for Custom Electrical Contacts are designed to be efficient and effective. Once the design is finalized, we use advanced manufacturing techniques, such as 3D printing, CNC machining, and rapid tooling, to produce high – quality prototypes. This allows us to quickly bring the design from the digital realm to a physical model for testing and evaluation.

We can create prototypes with varying levels of fidelity, from functional models for performance testing to fully finished prototypes for aesthetic evaluation. Our prototyping process enables clients to assess the form, fit, and function of the custom electrical contacts in real – world scenarios. Based on the test results and client feedback, we can make necessary adjustments to the design before moving into full – scale production, saving time and resources in the long run.

Rigorous Quality Control in Electrical Contact Design

Quality control is integral to our Custom Electrical Contact Design, Engineering Support, and Prototyping Services. At every stage, from the initial design concept to the final prototype, we have strict quality control measures in place. Our design files are reviewed by multiple engineers to ensure accuracy and compliance with industry standards.

During prototyping, each component is inspected for dimensional accuracy, material integrity, and surface finish. We conduct a series of tests on the prototypes, including electrical performance tests, mechanical strength tests, and environmental resistance tests. Only when the prototypes meet all the predefined quality criteria do we consider the design ready for production. This rigorous quality control ensures that our custom electrical contacts are of the highest quality and reliability.

Comprehensive Customer Support for Electrical Contacts

We are committed to providing comprehensive customer support for our Custom Electrical Contact Design services. Our support team, consisting of customer service representatives, engineers, and project managers, is available throughout the entire project lifecycle. We offer detailed consultations during the initial design phase, helping clients define their requirements and choose the best design options.

During prototyping and production, we keep clients informed of the progress, providing regular updates and addressing any concerns promptly. In the post – project phase, we offer after – sales support, including assistance with installation, troubleshooting, and maintenance. We also welcome feedback from clients to continuously improve our services, aiming to build long – term, mutually beneficial relationships.