Advanced Manufacturing Infrastructure for Electrical Contacts

As providers of high-volume electrical contact production, our success hinges on our advanced manufacturing infrastructure. We’ve invested in state-of-the-art automated production lines designed to handle large-scale output without compromising precision. Our facilities are equipped with high-speed stamping presses, robotic assembly systems, and computer numerical control (CNC) machines, all programmed to maintain tight tolerances across thousands of units.

This infrastructure allows us to streamline processes, from raw material loading to final inspection. For example, our progressive die stamping systems can produce complex contact geometries at rates exceeding 1,000 parts per minute, ensuring efficiency for industrial suppliers. We also integrate real-time monitoring systems into our lines, which track parameters like temperature, pressure, and material flow to identify and address deviations immediately. This level of automation not only boosts output but also ensures that every electrical contact meets the same rigorous standards, batch after batch.

Rigorous Quality Control in High-Volume Electrical Contacts

Consistent quality is non-negotiable in high-volume production, which is why we’ve built a multi-layered quality control system for our electrical contacts. Every raw material—whether copper, stainless steel, or specialized alloys—undergoes testing for chemical composition, conductivity, and mechanical strength before entering production. In-line sensors and vision systems then inspect each contact during stamping, plating, and assembly to detect defects like misalignments, surface flaws, or inconsistent plating thickness.

Post-production, we conduct statistical process control (SPC) sampling, where random batches are tested for electrical resistance, contact force, and durability. For example, our endurance testing machines simulate millions of mating cycles to ensure contacts withstand real-world use. By combining automated inspections with manual audits, we maintain a defect rate well below industry standards, giving industrial suppliers confidence in the reliability of our products.

Material Optimization for High-Volume Electrical Contacts

Selecting the right materials is critical for high-volume electrical contacts, balancing cost, performance, and scalability. We work with suppliers to source premium materials in bulk, such as oxygen-free copper for high conductivity or beryllium copper for spring applications, leveraging economies of scale to keep costs competitive. Our material engineers also specialize in surface treatments, like nickel or gold plating, to enhance corrosion resistance and reduce friction without compromising conductivity.

For instance, in automotive applications, we use tin-plated copper contacts for their balance of affordability and reliability in moderate-current environments. In industrial settings, where contacts face harsh conditions, we might specify silver-plated alloys to minimize arcing. By optimizing material selection for each application, we ensure our high-volume production meets the diverse needs of industrial suppliers while maintaining consistent performance.

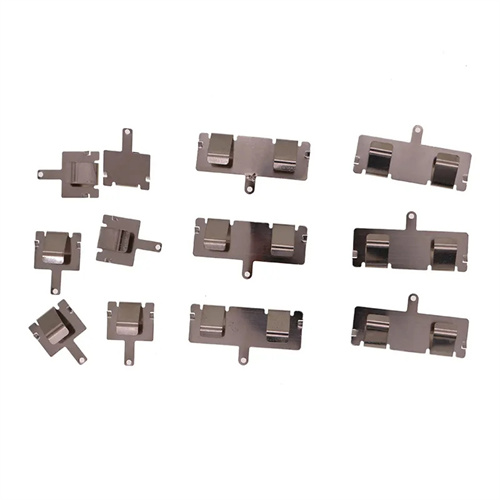

Customization at Scale for Electrical Contacts

High-volume production doesn’t mean sacrificing customization. Our flexible manufacturing setup allows us to adapt tooling and processes to meet unique specifications for electrical contacts. Whether a client needs a specific contact geometry, plating thickness, or packaging solution, our engineering team collaborates closely to develop cost-effective prototypes. For example, we’ve created specialized contacts with integrated locking features for aerospace clients and compact, low-profile designs for consumer electronics manufacturers—all within high-volume production runs.

We also offer modular tooling, which enables quick changeovers between product lines, reducing downtime and allowing us to handle multiple projects simultaneously. This agility ensures that industrial suppliers can access tailored solutions without the lengthy lead times typically associated with customization, making us a versatile partner for diverse market demands.

Logistical Excellence in High-Volume Electrical Contacts

Efficient logistics are key to supporting industrial suppliers in high-volume operations. We maintain strategically located warehouses and partner with global shipping networks to ensure timely delivery, whether distributing components across a city or across continents. Our inventory management systems use demand forecasting to prevent stockouts, while just-in-time (JIT) delivery options help clients reduce warehousing costs.

For large orders, we offer bulk packaging solutions that minimize handling and maximize storage efficiency. Our team also provides detailed documentation, including material certifications and test reports, to meet regulatory requirements in industries like automotive and aerospace. By optimizing every step of the supply chain, we ensure that our high-volume electrical contacts reach clients safely, on schedule, and in perfect condition.

Partnership-Driven Support for Industrial Suppliers

At the core of our high-volume electrical contact production is a commitment to partnership. We view our industrial clients as collaborators, working together to solve challenges and drive innovation. Our technical support team is available to assist with design reviews, troubleshooting, and performance optimization, even after production begins. For example, we’ve helped clients refine contact designs to reduce material waste or improve assembly speed, enhancing their overall efficiency.

We also prioritize transparency, providing regular updates on production progress and quality metrics. By fostering open communication and delivering consistent, reliable products, we aim to be more than a supplier—we strive to be a trusted extension of our clients’ teams. In an industry where precision and scalability are paramount, our focus on partnership ensures that high-volume electrical contact production meets the evolving needs of modern industrial supply chains.