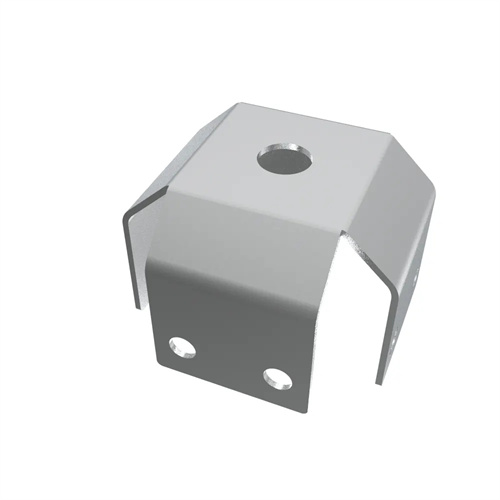

Dual-Functionality Design of Metal U Clip Fasteners

Our Electronics Metal U Clip Fasteners are engineered with a dual-focus on EMI (Electromagnetic Interference) shielding and component retention, addressing two critical challenges in modern electronics. The U-shaped geometry serves as both a mechanical fastener and an electromagnetic barrier. The arms of the clip securely hold components in place, preventing movement that could cause electrical failures or signal disruptions. Meanwhile, the conductive metal material—typically stainless steel or copper alloy—forms a Faraday cage around sensitive components, blocking unwanted EMI and RFI (Radio Frequency Interference).

This dual functionality eliminates the need for separate shielding and fastening components, streamlining assembly and reducing material costs. For example, in smartphones or laptops, our clips can secure a battery or circuit board while simultaneously shielding the device’s internal electronics from external interference. By integrating these two essential functions into a single part, we provide a space-efficient solution that enhances both the reliability and performance of electronic devices.

Advanced Materials for EMI Shielding in Metal U Clip Fasteners

The effectiveness of our Metal U Clip Fasteners in EMI shielding relies on strategic material selection. We prioritize high-conductivity metals like copper and its alloys, which efficiently reflect and absorb electromagnetic waves. For applications requiring additional corrosion resistance, we use nickel-plated or tin-plated steel, ensuring the clip maintains its shielding properties even in humid or high-temperature environments.

In high-frequency applications, such as aerospace electronics or telecommunications equipment, we may specify silver-plated clips for their superior conductivity at RF wavelengths. These materials are precision-stamped to form a continuous conductive path when attached to a grounded chassis, creating a seamless shield against EMI. By matching material properties to the specific EMI challenges of each application, our clips deliver optimal shielding performance while ensuring robust component retention.

Precision Engineering for Secure Component Retention

Component retention is equally critical in our Metal U Clip Fasteners. The U-shape is designed with calculated spring tension, allowing the clip to grip components firmly without causing damage. Our engineers use finite element analysis (FEA) to optimize the clip’s arm thickness, curvature, and opening width, ensuring it can withstand vibrations, thermal expansion, and repeated assembly cycles.

For example, in automotive electronics, where components must endure constant motion, our clips feature interlocking teeth or serrated edges to enhance grip. In consumer devices, the sleek design of our clips ensures they fit within tight spaces while providing a secure hold for delicate components like cameras or sensors. This precision engineering guarantees that our fasteners keep components stable throughout the device’s lifecycle, reducing the risk of loose connections or mechanical failure.

Manufacturing Excellence for Metal U Clip Fasteners

Our manufacturing process for Electronics Metal U Clip Fasteners combines high-speed stamping with meticulous quality control. We use progressive dies to produce clips with micron-level precision, ensuring consistent spring force and dimensional accuracy across millions of units. Automated inline sensors measure key parameters like arm spacing and material thickness, flagging any deviations for immediate adjustment.

After stamping, clips undergo a series of surface treatments to enhance performance. EMI shielding efficiency is tested using specialized equipment that measures shielding effectiveness (SE) across a range of frequencies. For component retention, we conduct pull-out tests to ensure the clips meet or exceed industry standards for holding force. This rigorous process ensures that every clip delivers reliable EMI protection and secure component retention, batch after batch.

Diverse Applications in Electronics for Metal U Clip Fasteners

Our Metal U Clip Fasteners are indispensable in a wide array of electronic applications. In data centers, they secure server components while shielding against EMI generated by high-speed data transfers. In medical devices like MRI machines, non-magnetic stainless steel clips provide EMI shielding without interfering with sensitive imaging. For electric vehicles (EVs), our clips retain battery modules and shield the vehicle’s infotainment system from motor-generated interference.

Consumer electronics also benefit from our dual-function design. In wireless earbuds, tiny copper clips hold the battery and Bluetooth module in place while blocking EMI that could degrade audio quality. In laptops, our clips secure the motherboard and shield the Wi-Fi antenna from electromagnetic noise. Across industries, our fasteners offer a versatile solution for balancing mechanical stability and electromagnetic compatibility.

Customer-Centric Support for Metal U Clip Fasteners

We pride ourselves on delivering end-to-end support for our Electronics Metal U Clip Fasteners. Our team of EMI shielding experts and mechanical engineers collaborates with clients to design custom solutions, whether adapting clip dimensions for a unique component or selecting the ideal material for specific frequency ranges. We provide detailed shielding effectiveness reports and mechanical performance data to help clients validate our clips in their designs.

For production-scale orders, our logistics team ensures on-time delivery with just-in-time (JIT) inventory management. Post-installation, our customer service team is available to troubleshoot issues or provide design updates for next-generation products. By combining technical expertise with responsive support, we aim to be more than a supplier—we strive to be a partner in solving our clients’ most complex EMI and component retention challenges.