Superior Material Selection for Metal U Clip Fasteners

Our High-Tensile Metal U Clip Fasteners owe their exceptional durability to the careful selection of superior materials. In harsh environments, where components are exposed to extreme temperatures, corrosive substances, and high mechanical stresses, the choice of material is crucial. We primarily utilize high-grade alloys, such as stainless steel with high nickel and chromium content, as well as specialized titanium alloys.

Stainless steel offers excellent corrosion resistance, protecting the clips from rust and degradation caused by moisture, salt, and chemicals. The addition of nickel and chromium enhances its strength and ability to withstand high tensile forces. Titanium alloys, on the other hand, provide a high strength-to-weight ratio, making them ideal for applications where weight is a concern while still maintaining robust tensile strength. These materials are carefully sourced and tested to ensure they meet our strict standards, forming the foundation for our reliable Metal U Clip Fasteners in challenging conditions.

Innovative Design for Harsh Environments in Metal U Clip Fasteners

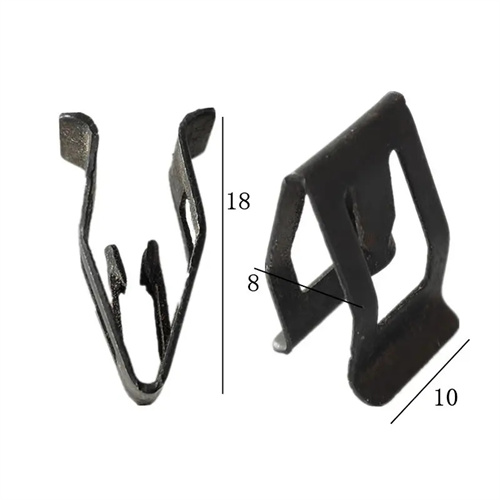

The design of our High-Tensile Metal U Clip Fasteners is tailored to meet the demands of harsh environments. We incorporate features that enhance their resistance to mechanical stress and environmental factors. The U-shape of the clips is optimized with precise angles and curvature to distribute loads evenly, reducing the risk of stress concentrations that could lead to failure.

The arms of the clips are designed with increased thickness and robust cross-sections to withstand high tensile forces. Additionally, we may include features such as serrated edges or textured surfaces to improve grip and prevent components from slipping out, even under heavy vibrations or sudden shocks. For environments with high humidity or corrosive substances, we design the clips to minimize crevices where moisture or chemicals could accumulate, further enhancing their durability. This innovative design approach ensures that our Metal U Clip Fasteners can perform reliably in the most demanding conditions.

Exceptional Performance in Harsh Conditions of Metal U Clip Fasteners

Our High-Tensile Metal U Clip Fasteners deliver exceptional performance in harsh environments. They can withstand extreme temperature variations, from freezing cold to high heat, without losing their mechanical properties. In applications such as oil and gas exploration in frigid arctic regions or industrial furnaces with intense heat, our clips maintain their strength and integrity, providing a secure fastening solution.

Against corrosive elements, whether it’s the saltwater spray in marine environments or the chemical exposure in industrial plants, our clips resist degradation. Their high tensile strength allows them to hold components firmly in place, even when subjected to continuous vibrations, heavy loads, or sudden impacts. This reliable performance reduces the need for frequent replacements and maintenance, saving both time and costs for our customers operating in harsh conditions.

Meticulous Manufacturing Process of Metal U Clip Fasteners

The production of our High-Tensile Metal U Clip Fasteners involves a meticulous manufacturing process. We start with the selection of raw materials from trusted suppliers, ensuring that they meet our stringent quality requirements. The materials are then processed using advanced techniques, such as precision stamping and forging.

During precision stamping, state-of-the-art equipment is used to shape the metal into the desired U – clip form with exacting tolerances. Forging, when applicable, further enhances the mechanical properties of the clips by improving their grain structure and density. After shaping, the clips undergo a series of heat treatments to optimize their strength, hardness, and toughness. Each clip is then rigorously inspected for dimensional accuracy, surface finish, and mechanical performance. Only those that pass all the tests are approved for use, guaranteeing that our Metal U Clip Fasteners meet the highest quality standards.

Diverse Applications in Harsh Environments of Metal U Clip Fasteners

Our High-Tensile Metal U Clip Fasteners find diverse applications in various industries with harsh environments. In the automotive industry, especially for off-road vehicles and heavy-duty trucks operating in rugged terrains, these clips are used to secure components that are exposed to vibrations, shocks, and mud.

In the aerospace sector, they play a crucial role in aircraft components that endure extreme altitudes, temperature changes, and aerodynamic forces. The oil and gas industry relies on our clips for fastening equipment in offshore platforms and drilling sites, where they must withstand saltwater corrosion and high mechanical loads. Additionally, in industrial manufacturing plants with exposure to chemicals and high temperatures, our Metal U Clip Fasteners provide a reliable fastening solution for various machinery and equipment.

Comprehensive Customer Support for Metal U Clip Fasteners

We are committed to providing comprehensive customer support for our High-Tensile Metal U Clip Fasteners. Our team of experts, including engineers, technicians, and customer service representatives, is available to assist customers throughout the entire process, from product selection to after-sales service. We offer detailed technical advice on choosing the right type of clip for specific harsh environments, taking into account factors such as temperature range, corrosive substances, and mechanical loads.

In case of any issues or concerns, our responsive after-sales service team is ready to provide prompt solutions. Whether it’s a question about product performance, a need for replacement parts, or assistance with installation, we strive to ensure that our customers are completely satisfied with our products and services. We also welcome feedback from our customers to continuously improve our offerings, aiming to build long-term relationships based on trust, reliability, and exceptional support in the market for durable fastening solutions.