Superior Corrosion-Resistant Material of Metal U Clip Fasteners

Our Stainless Steel Metal U Clip Fasteners owe their exceptional durability to the superior corrosion – resistant properties of stainless steel. Composed primarily of iron, chromium, nickel, and other alloying elements, stainless steel forms a thin, invisible passive film on its surface when exposed to oxygen. This passive film acts as a protective barrier, preventing the underlying metal from reacting with moisture, chemicals, and other corrosive agents in the environment.

The chromium content in stainless steel is particularly crucial, as it significantly enhances the material’s resistance to oxidation and rust. Different grades of stainless steel, such as 304 and 316, offer varying levels of corrosion resistance, allowing us to select the most suitable type for different applications. Whether it’s exposure to saltwater, acidic substances, or high humidity, our Metal U Clip Fasteners maintain their structural integrity and functionality, making them a reliable choice for long – term use in challenging environments.

Optimal Design for Retaining Function in Metal U Clip Fasteners

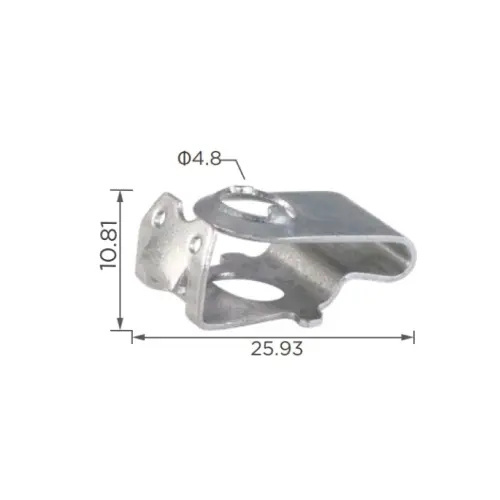

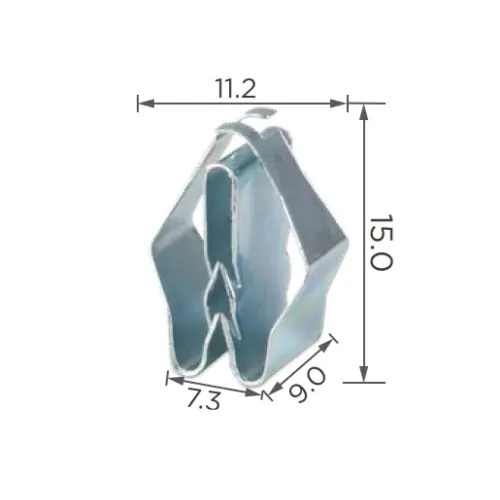

The design of our Stainless Steel Metal U Clip Fasteners is optimized to provide an efficient retaining function. The U – shape of the clips offers a simple yet highly effective locking mechanism. The arms of the clip are carefully engineered to apply consistent pressure, ensuring a secure grip on the components they hold in place. This design allows for quick and easy installation, reducing assembly time and labor costs.

For enhanced retention, many of our Metal U Clip Fasteners feature serrated edges or textured surfaces. These details increase the friction between the clip and the retained component, preventing slippage even under vibrations or mechanical stress. Additionally, the curvature and dimensions of the U – shape are precisely calculated to accommodate a wide range of component sizes, providing a versatile and reliable solution for various fastening needs. Whether it’s securing pipes, wires, or mechanical parts, our clips ensure a stable and long – lasting connection.

Meticulous Manufacturing Process of Metal U Clip Fasteners

The production of our Stainless Steel Metal U Clip Fasteners involves a meticulous manufacturing process to guarantee top – notch quality. We begin by sourcing high – grade stainless steel from trusted suppliers, ensuring that the material meets strict standards for chemical composition and mechanical properties. Our manufacturing facilities are equipped with advanced stamping and forming equipment.

The stainless steel sheets are fed into high – precision stamping machines, where they are shaped into the U – clip form with exacting tolerances. After stamping, the clips undergo a series of quality control checks. Automated inspection systems verify the dimensions, surface finish, and structural integrity of each clip. To further enhance their corrosion resistance, some clips may undergo additional surface treatments, such as passivation or electropolishing. Only clips that pass these rigorous inspections are approved for use, ensuring that our customers receive Metal U Clip Fasteners of the highest quality.

Reliable Performance in Harsh Environments of Metal U Clip Fasteners

Our Stainless Steel Metal U Clip Fasteners deliver reliable performance in even the harshest environments. In marine applications, where exposure to saltwater and high humidity can quickly corrode ordinary metal fasteners, our clips remain unaffected, securely holding components on ships, offshore platforms, and coastal installations.

In industrial settings with exposure to chemicals, acids, or alkaline substances, our Metal U Clip Fasteners maintain their strength and integrity, ensuring the stability of equipment and machinery. They can also withstand extreme temperature fluctuations, from freezing cold to high heat, without losing their corrosion resistance or mechanical properties. This reliable performance reduces the need for frequent replacements and maintenance, saving both time and costs for our customers across various industries.

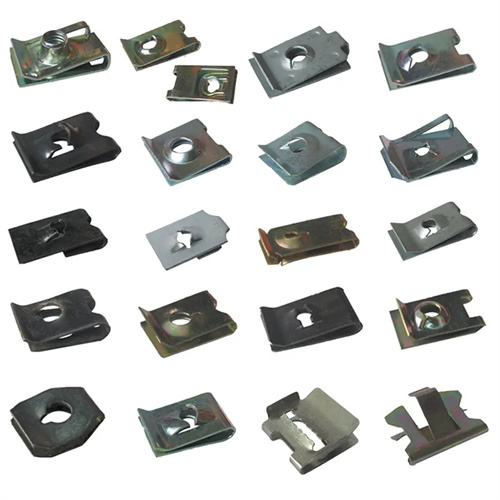

Diverse Applications of Metal U Clip Fasteners

Our Stainless Steel Metal U Clip Fasteners find diverse applications across multiple industries. In the automotive sector, they are used to secure fuel lines, wiring harnesses, and exhaust components, protecting them from corrosion caused by road salts and moisture.

In the construction industry, these clips are employed to fasten pipes, ducts, and insulation materials, ensuring a long – lasting connection even in outdoor environments. In the food and beverage industry, where hygiene and corrosion resistance are paramount, our Metal U Clip Fasteners are used in processing equipment and machinery. Additionally, they are popular in the electronics, aerospace, and medical device industries, providing a secure and reliable fastening solution for a wide range of components.

Comprehensive Customer Support for Metal U Clip Fasteners

We are committed to providing comprehensive customer support for our Stainless Steel Metal U Clip Fasteners. Our team of experts, including engineers, technicians, and customer service representatives, is available to assist customers throughout the entire process, from product selection to after – sales service. We offer detailed technical advice on choosing the right type of clip for specific applications, taking into account factors such as environmental conditions, load requirements, and component sizes.

In case of any issues or concerns, our responsive after – sales service team is ready to provide prompt solutions. Whether it’s a question about product performance, a need for replacement parts, or assistance with installation, we strive to ensure that our customers are completely satisfied with our products and services. We also welcome feedback from our customers to continuously improve our offerings, aiming to build long – term relationships based on trust, reliability, and exceptional support in the market for corrosion – resistant fastening solutions.