The Crucial Significance of OEM Certification for Terminal Connectors

As manufacturers of Automotive Terminal Connectors, we fully recognize the crucial significance of OEM (Original Equipment Manufacturer) certification. This certification is not just a mark of quality; it represents a comprehensive validation of our products’ ability to meet the exacting standards set by leading automotive brands. To obtain OEM approval, our Terminal Connectors must undergo rigorous testing and evaluation across multiple aspects, including electrical conductivity, mechanical strength, durability, and compatibility with vehicle wiring systems.

Automotive OEMs have strict requirements for every component in vehicle production to ensure safety, reliability, and seamless integration. Our OEM – certified Terminal Connectors offer automotive manufacturers the confidence that our products will perform flawlessly in their vehicles, reducing the risk of electrical failures and enhancing overall vehicle quality. For aftermarket suppliers and repair shops, this certification also means that they can rely on our connectors to meet the same high – standards as original factory parts, providing peace of mind during repairs and replacements.

Superior Performance Attributes of Terminal Connectors

Our Automotive Terminal Connectors are engineered to deliver superior performance attributes essential for vehicle wiring systems. In terms of electrical conductivity, we use high – quality materials, such as copper or copper alloys with excellent conductivity, to ensure minimal electrical resistance. This allows for efficient power transmission and signal transfer, reducing energy losses and preventing overheating in the wiring system.

Mechanically, our Terminal Connectors are designed to withstand the harsh conditions inside a vehicle. They can endure vibrations, shocks, and temperature fluctuations without loosening or failing. The connectors feature robust locking mechanisms that provide a secure connection, preventing accidental disconnection. Additionally, many of our connectors are designed with moisture – resistant and corrosion – resistant features, protecting against environmental factors that could compromise their performance, ensuring long – term reliability in vehicle electrical systems.

Meticulous Design and Manufacturing of Terminal Connectors

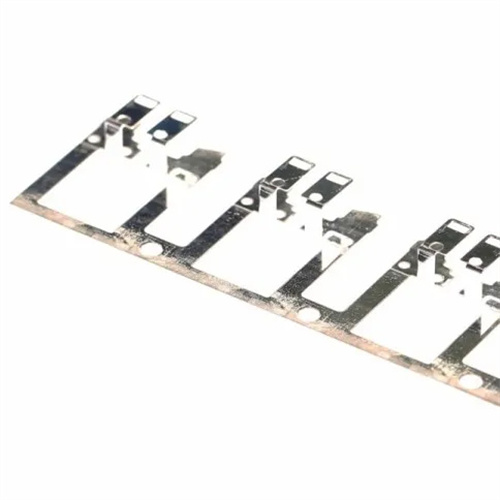

The production of our Automotive Terminal Connectors involves a meticulous design and manufacturing process. We begin by collaborating closely with automotive OEMs to understand the specific requirements of their vehicle wiring systems. Our team of experienced engineers uses advanced design software to create connector designs that optimize functionality, durability, and ease of installation.

In the manufacturing stage, we utilize state – of – the – art production equipment and techniques. Precision stamping, injection molding, and assembly processes are employed to produce Terminal Connectors with consistent quality and exacting tolerances. Each step of the manufacturing process is closely monitored by our quality control team, from raw material inspection to the final assembly and testing of the connectors. This attention to detail ensures that every connector leaving our facility meets the highest standards of quality and performance.

Rigorous Quality Control for Terminal Connectors

Quality control is at the heart of our production of Automotive Terminal Connectors. We have established a comprehensive quality management system that adheres to both OEM requirements and international industry standards. Our quality control team conducts thorough inspections at every stage of production.

Raw materials are carefully tested for their electrical, mechanical, and chemical properties to ensure they meet our strict specifications. During the manufacturing process, in – line inspections are carried out using advanced testing equipment to check for dimensional accuracy, surface finish, and proper assembly. After production, each batch of Terminal Connectors undergoes a series of rigorous tests, including electrical performance testing, mechanical strength testing, and environmental resistance testing. Only connectors that pass all these strict quality checks are approved for shipment, guaranteeing that our OEM – certified products maintain their reputation for excellence.

Diverse Applications of Terminal Connectors in Vehicle Wiring Systems

Our OEM – certified Automotive Terminal Connectors find diverse applications within vehicle wiring systems. They are essential components in engine control units, where they ensure reliable electrical connections for sensors and actuators, enabling precise engine management. In the vehicle’s lighting systems, our connectors play a crucial role in powering headlights, taillights, and interior lights, providing a stable electrical supply.

For the vehicle’s infotainment and communication systems, our Terminal Connectors facilitate the transfer of audio, video, and data signals. They are also used in power distribution systems, battery connections, and various electrical subsystems throughout the vehicle. Whether it’s a compact car, a luxury sedan, or a heavy – duty truck, our connectors are engineered to meet the specific electrical requirements of different vehicle types, ensuring the smooth operation of the entire wiring system.

Comprehensive Customer Support for Terminal Connectors

We are committed to providing comprehensive customer support for our Automotive Terminal Connectors. Our team of experts, including automotive engineers, technicians, and customer service representatives, is available to assist customers throughout the entire process, from product selection to after – sales service. We offer detailed technical advice on choosing the right type of connector for specific vehicle wiring applications, taking into account factors such as electrical load, wire gauge, and environmental conditions.

In case of any issues or concerns, our responsive after – sales service team is ready to provide prompt solutions. Whether it’s a question about product performance, a need for replacement parts, or assistance with installation, we strive to ensure that our customers are completely satisfied with our products and services. We also welcome feedback from our customers to continuously improve our offerings, aiming to build long – term relationships based on trust, reliability, and exceptional support in the automotive industry.