In the intricate world of electrical products, battery contacts stand as essential components that underpin the reliable operation and functionality of countless devices. These unassuming yet crucial elements serve as the vital link between batteries and the electrical systems within products, facilitating the seamless transfer of electrical energy. From small handheld gadgets to complex industrial equipment, battery contacts play a pivotal role in ensuring that electrical products perform optimally, providing users with consistent and efficient performance. Let’s explore the diverse ways in which we rely on battery contacts in the realm of electrical products.

1.The Fundamental Role of Battery Contacts in Electrical Products

Battery contacts are the cornerstone for establishing a stable electrical connection in electrical products. Their primary function is to enable the flow of electricity from the battery to the product’s internal circuits, powering its various components. Whether it’s a remote control for a television, a cordless phone, or a portable gaming console, battery contacts ensure that the electrical current reaches the necessary parts of the device, allowing it to function as intended. By creating a low – resistance pathway, these contacts minimize energy loss during transmission, which is crucial for maximizing the efficiency and battery life of the product. A reliable set of battery contacts is essential for preventing issues such as intermittent power supply, reduced performance, or complete device failure, ensuring a seamless user experience.

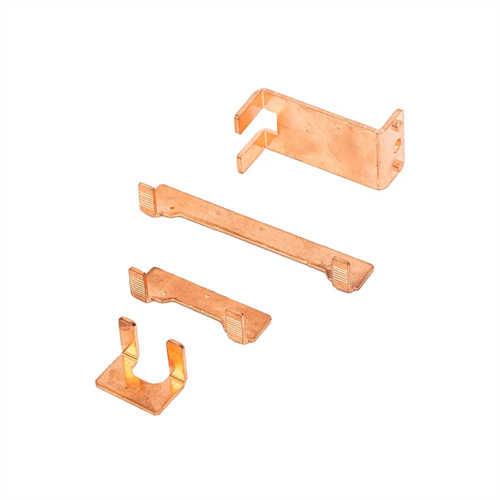

2.Materials and Durability of Battery Contacts for Electrical Products

The choice of materials for battery contacts in electrical products is a critical factor that significantly impacts their performance and lifespan. We prioritize materials with excellent electrical conductivity, corrosion resistance, and mechanical strength. Brass is a commonly used material due to its good electrical properties and relatively low cost, making it suitable for a wide range of consumer – grade electrical products. Phosphor bronze, on the other hand, offers superior spring characteristics, allowing it to maintain a secure and consistent connection with the battery even after repeated insertions and removals. Stainless steel is often preferred in applications where exposure to harsh environmental conditions, such as moisture or chemicals, is expected, as it provides exceptional corrosion resistance. Additionally, noble metals like gold or silver may be used for their high conductivity and resistance to oxidation in high – end or specialized electrical products, ensuring long – lasting and reliable performance.

3.Design Considerations for Battery Contacts in Electrical Product Manufacturing

Designing effective battery contacts for electrical products involves a careful balance of multiple factors. The shape, size, and configuration of the contacts must be precisely tailored to the specific requirements of each product, including the type of battery used, the internal layout, and the expected usage patterns. In compact devices like smartphones or smartwatches, where space is at a premium, highly miniaturized and efficient contact designs are essential. We often incorporate features such as spring – loaded contacts or locking mechanisms to ensure a secure fit with the battery, preventing accidental disconnections during normal use or when the device is subject to vibrations or impacts. Moreover, the design of battery contacts also takes into account ease of manufacturing, assembly, and maintenance, as well as compliance with safety standards to prevent risks such as short circuits or electrical shocks.

4.Diverse Applications of Battery Contacts in Electrical Products

Battery contacts find extensive use across a wide spectrum of electrical products, each with its unique operational demands. In consumer electronics, they are integral to devices such as laptops, tablets, and digital cameras, ensuring a reliable power supply for seamless operation. In the automotive industry, battery contacts are used in key fobs, tire pressure monitoring systems, and various in – car accessories, enabling convenient functionality and enhanced safety features. In the industrial sector, battery – powered tools, sensors, and control devices rely on battery contacts to provide the necessary power for efficient operation in demanding environments. Even in home appliances like cordless vacuum cleaners and remote – controlled ceiling fans, battery contacts play a crucial role in delivering a convenient and hassle – free user experience. The versatility of battery contacts makes them an indispensable component in the development and functionality of countless electrical products.

5.Future Trends and Innovations of Battery Contacts in Electrical Products

As the electrical product industry continues to evolve with advancements in technology, battery contacts are also set to undergo significant transformations. With the increasing adoption of rechargeable batteries, especially lithium – ion batteries, and the development of more energy – efficient electrical systems, battery contacts will need to be optimized to handle higher currents and voltages while maintaining high levels of efficiency. Future trends may include the integration of smart features into battery contacts, such as built – in sensors that can monitor battery health, charge levels, and connection quality in real – time, enabling proactive maintenance and improved user experience. Additionally, the growing demand for smaller, lighter, and more compact electrical products will drive the development of even more miniaturized and innovative contact designs. The emergence of new materials and manufacturing techniques, such as nanotechnology and 3D printing, may also open up new possibilities for creating battery contacts with enhanced performance and durability.