As we delve into the intricate world of electronic products, electrical contacts emerge as indispensable components that underpin the functionality and reliability of these devices. From the smartphones we hold in our hands to the complex servers that power the internet, electrical contacts play a crucial role in enabling electrical connections, facilitating signal transmission, and ensuring seamless operation. In this article, we will explore the diverse applications of electrical contacts in electronic products, highlighting their significance and the challenges associated with their design and implementation.

1.Electrical Contacts in Smartphones and Wearable Devices

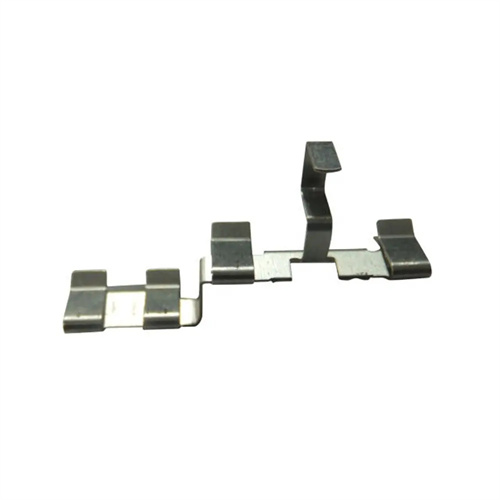

In our daily lives, smartphones and wearable devices have become an extension of ourselves, and electrical contacts are at the heart of their functionality. These devices rely on a multitude of electrical contacts to establish connections between various components, such as the battery, display, camera, and sensors. For example, the connectors that link the battery to the motherboard use electrical contacts to ensure a stable power supply. Similarly, the connectors for the display and camera modules rely on precise electrical contacts to transmit data and signals. In wearable devices, such as smartwatches and fitness trackers, electrical contacts are used to connect the device to the charger and to interface with other accessories. The miniaturization of electrical contacts in these devices is a key challenge, as they need to be small enough to fit into the compact form factor of smartphones and wearables while still maintaining reliable performance.

2.Electrical Contacts in Computers and Laptops

Computers and laptops are essential tools for work, study, and entertainment, and electrical contacts are integral to their operation. Inside these devices, electrical contacts are used to connect the motherboard to various components, such as the CPU, memory modules, hard drives, and graphics cards. The connectors used in these devices are designed to provide a secure and reliable connection, ensuring that data and power can be transmitted efficiently. For example, the socket connectors for the CPU use a series of electrical contacts to establish a connection between the processor and the motherboard. Similarly, the memory modules are connected to the motherboard using electrical contacts that allow for high – speed data transfer. In addition to internal connections, electrical contacts are also used for external interfaces, such as USB ports, HDMI ports, and Ethernet ports. These ports use electrical contacts to establish a connection between the computer and external devices, enabling data transfer and communication.

3.Electrical Contacts in Consumer Electronics

Consumer electronics, such as televisions, audio systems, and gaming consoles, also rely on electrical contacts for their operation. In televisions, electrical contacts are used to connect the various components, such as the display panel, tuner, and audio system. The connectors used in these devices are designed to provide a high – quality connection, ensuring that the video and audio signals are transmitted without loss or distortion. For example, the HDMI connectors used in modern televisions use electrical contacts to transmit high – definition video and audio signals. Similarly, in audio systems, electrical contacts are used to connect the speakers, amplifier, and other components. The quality of the electrical contacts in these devices can have a significant impact on the sound quality, as poor contacts can result in noise, distortion, and loss of signal. In gaming consoles, electrical contacts are used to connect the controller, memory cards, and other accessories. These contacts need to be highly reliable and responsive to ensure a smooth gaming experience.

4.Electrical Contacts in Industrial Electronics

Industrial electronics, such as programmable logic controllers (PLCs), industrial computers, and automation systems, operate in harsh environments and require highly reliable electrical contacts. In these applications, electrical contacts are used to connect various components, such as sensors, actuators, motors, and control panels. The connectors used in industrial electronics are designed to withstand extreme temperatures, vibrations, moisture, and dust. For example, the connectors used in automotive electronics need to be able to operate in high – temperature environments and withstand vibrations and shocks. Similarly, the connectors used in aerospace electronics need to be lightweight, compact, and able to withstand the rigors of space travel. In addition to environmental challenges, industrial electronics also require electrical contacts that can handle high currents and voltages, as well as provide high – speed data transfer.

5.Future Trends of Electrical Contacts in Electronic Products

As electronic products continue to evolve and become more sophisticated, the demand for high – performance electrical contacts is increasing. In the future, we can expect to see the development of new materials and technologies that will enable the creation of smaller, more reliable, and more efficient electrical contacts. For example, nanotechnology is being explored as a way to create ultra – small electrical contacts with improved conductivity and durability. Additionally, the use of advanced manufacturing techniques, such as 3D printing, is expected to revolutionize the production of electrical contacts, allowing for greater customization and flexibility. Another trend is the integration of electrical contacts with other components, such as sensors and actuators, to create intelligent and self – monitoring systems. These trends will not only improve the performance and reliability of electronic products but also open up new opportunities for innovation and development.