Advanced Design of EV Battery Contact Plates

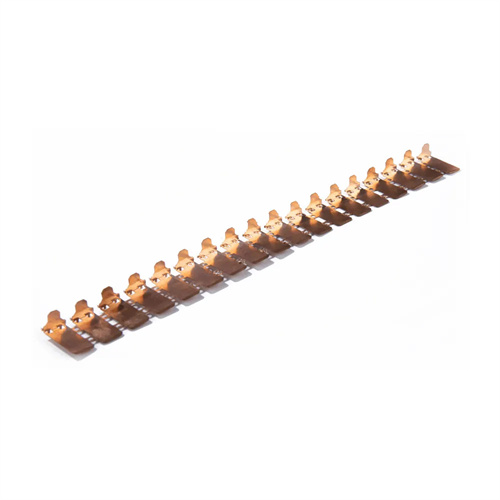

Our EV Battery Contact Plates are engineered with an advanced design that meets the high – performance demands of electric vehicles. We understand that in EVs, every component plays a crucial role in energy efficiency and vehicle safety. The contact plates are designed with a unique geometry that maximizes the contact area between the battery cells and the vehicle’s electrical system. This increased surface area reduces electrical resistance, enabling efficient energy transfer and minimizing power loss.

The plates also feature a modular design, which allows for easy installation and maintenance. They can be quickly assembled and disassembled, reducing the time and cost associated with battery pack servicing. Additionally, the design incorporates vibration – dampening elements, as electric vehicles often experience significant vibrations during operation. These elements ensure that the contact plates remain securely in place, preventing any loose connections that could lead to electrical failures.

Superior Material Selection for Battery Contact Plates

We take great care in selecting materials for our EV Battery Contact Plates to ensure superior performance. High – conductivity metals, such as copper and its alloys, are the primary choice for the base material. Copper offers excellent electrical conductivity, allowing for the seamless flow of high – voltage currents required by electric vehicles. To further enhance conductivity and prevent oxidation, we apply advanced surface treatments, such as gold or silver plating.

For the structural components of the contact plates, we use high – strength, lightweight materials like aluminum alloys. These materials provide the necessary mechanical support while reducing the overall weight of the battery pack, which is crucial for improving the vehicle’s range. The combination of these high – quality materials not only enhances the electrical performance of the contact plates but also ensures their durability and reliability in the demanding environment of electric vehicles.

Robust Safety Features of Battery Contact Plates

Safety is our top priority when it comes to EV Battery Contact Plates. Our contact plates are equipped with multiple safety features to prevent potential hazards. First, they are designed with insulation barriers made from flame – retardant materials. These barriers prevent short circuits and protect against electrical arcing, which could lead to fires.

The contact plates also incorporate a locking mechanism that ensures a secure connection between the battery cells and the vehicle’s electrical system. This mechanism prevents accidental disconnection during vehicle operation, even under extreme conditions such as high – speed driving or sudden stops. Additionally, we conduct rigorous testing on our contact plates, including high – voltage testing, thermal cycling, and impact testing, to ensure they meet and exceed industry safety standards.

Meticulous Manufacturing Process of Battery Contact Plates

The production of our EV Battery Contact Plates involves a meticulous manufacturing process. We start by sourcing the highest – quality raw materials from trusted suppliers. The manufacturing process begins with precision stamping and machining, where the metal is shaped into the desired form of the contact plate with extreme accuracy.

After shaping, the plates undergo a series of surface treatments, including plating and coating, to enhance their electrical and mechanical properties. Each plate is then carefully inspected for dimensional accuracy, surface finish, and electrical conductivity. Our quality control team uses advanced testing equipment, such as coordinate measuring machines and electrical testers, to ensure that every contact plate meets our strict quality standards. Only plates that pass all these rigorous tests are approved for use in electric vehicle battery packs.

Diverse Applications of EV Battery Contact Plates

Our EV Battery Contact Plates have diverse applications within the electric vehicle industry. They are essential components in battery packs for passenger cars, providing a reliable connection between the battery cells and the vehicle’s powertrain. In electric buses and trucks, our contact plates can handle the high – power demands of these larger vehicles, ensuring efficient energy transfer for long – distance travel.

For electric motorcycles and scooters, our compact and lightweight contact plates are ideal, as they help to reduce the overall weight of the vehicle while maintaining a stable electrical connection. Additionally, our contact plates are used in energy storage systems for electric vehicles, such as home charging stations and grid – connected charging infrastructure, enabling the seamless transfer of energy between the vehicle and the power source.

Comprehensive Customer Support for Battery Contact Plates

We are committed to providing comprehensive customer support for our EV Battery Contact Plates. Our team of experts is available to assist customers throughout the entire process, from the initial product selection to after – sales service. We offer detailed technical advice on choosing the right type of contact plate for specific electric vehicle models, taking into account factors such as battery capacity, voltage requirements, and vehicle design.

In case of any issues or concerns, our responsive after – sales service team is ready to provide prompt solutions. Whether it’s a question about product performance, a need for replacement parts, or assistance with installation, we strive to ensure that our customers are completely satisfied with our products and services. We also welcome feedback from our customers to continuously improve our offerings, aiming to build long – term relationships based on trust, reliability, and exceptional support in the electric vehicle industry.