As a supplier specializing in grounding battery spring contacts, we always take it as our responsibility to safeguard electrical safety, uphold the concept of “safe connection, stable protection”, and deeply cultivate the field of power connection. We are well aware that in the battery system, the grounding spring contact is a key defense line to ensure the safe operation of equipment and avoid electrical faults. Therefore, we integrate every craftsmanship and innovation into every aspect of product development and production.

During the product development process, our technical team conducted in-depth research on the working principle and performance requirements of the grounding system, and repeatedly optimized the structure and material of the spring contacts to address issues such as electrical interference and static electricity accumulation that battery equipment may face. The innovatively designed spring structure can maintain good elasticity under complex working conditions, ensuring the tightness and stability of the grounding connection. We use special conductive alloy materials as contact substrates, which have excellent conductivity and mechanical strength. They not only effectively reduce grounding resistance, quickly release static electricity and abnormal currents, but also have excellent fatigue resistance. Even in harsh environments such as frequent vibration and temperature changes, they can still work reliably.

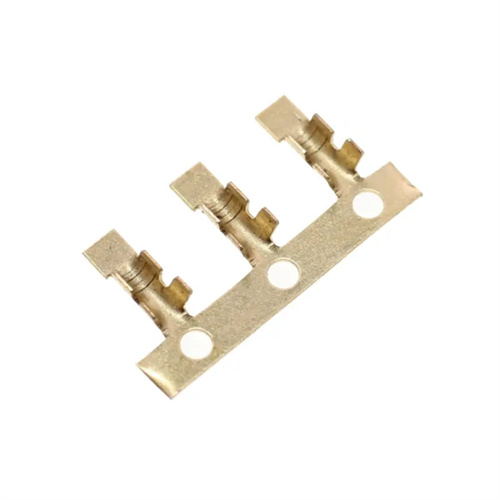

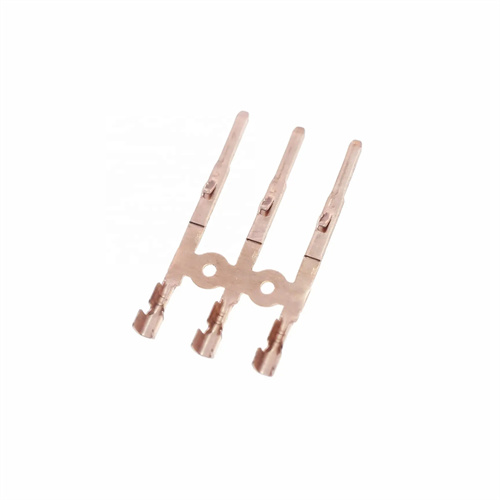

In terms of production and manufacturing, we have built intelligent and high-precision production lines that combine advanced stamping and forming technologies. From precise cutting of raw materials to precise machining of spring contacts, every process undergoes strict parameter control and real-time monitoring. To further enhance the protective performance of the product, we perform multiple surface treatments on the spring contacts, using processes such as tin plating and silver plating to enhance their oxidation and corrosion resistance, extend their service life, and ensure long-term stability of grounding performance. At the same time, we introduce automated testing equipment to quickly and accurately detect key indicators such as dimensional accuracy, conductivity, and contact pressure of each spring contact, ensuring consistency in product quality.

Quality control is one of our core competencies. We have established a comprehensive quality traceability system, which can trace every step from raw material procurement to finished product delivery. By simulating extreme environmental tests such as high temperature and humidity, strong electromagnetic interference, etc., the grounding performance of spring contacts is rigorously tested. In addition, we regularly conduct fatigue life tests on our products to ensure that they maintain a stable and reliable grounding effect throughout long-term use. Each batch of products undergoes strict quality audits, and only grounding battery spring contacts that fully comply with international standards and customer requirements can be delivered to customers.

With excellent product performance and reliable quality, our grounding battery spring contacts have been widely used in multiple fields such as new energy vehicles, energy storage power stations, communication base stations, and industrial automation equipment. In the battery management system of new energy vehicles, our product effectively ensures the safety of battery grounding and prevents leakage accidents from occurring; In energy storage power plants, stable grounding connections ensure the safe operation of equipment during charging and discharging processes. In the future, we will continue to increase research and development investment, constantly explore new technologies and processes, and provide customers with higher quality and safer solutions for grounding battery spring contacts. We will work together with customers to build a defense line for power safety.

Battery contact also known as contact shrapnel, battery spring contact, etc., is an important part of the battery, which is used to connect the positive and negative poles of the battery. According to different classification standards, battery shrapnel can be divided into different types.

According to different materials, battery contact shrapnes can be divided into copper, iron, stainless steel and other types. Battery shrapnel of different materials has different electrical conductivity and corrosion resistance, so it is suitable for different types of batteries.

According to the different shapes, battery contact can be divided into two types: straight and bent. Straight tabs are usually used for prismatic cells, while bent tabs are usually used for round cells.

According to different uses, battery contact / shrapnel can be divided into two types: single-sided shrapnel and double-sided shrapnel. Single-sided shrapnel is usually used for the connection of the positive or negative electrode, while double-sided shrapnel is usually used for the connection between the positive and negative electrodes.

In short, different types of battery shrapnel have different characteristics and application scenarios, and choosing the right shrapnel is very important to ensure the normal use and safety of the battery.

The Ground Battery Spring Contact offers the following features and advantages:

Reliable grounding connection: stable and low resistance connection can be established between the battery and the grounding system, which can effectively lead the charge to the ground and guarantee the safety of equipment and users.

Elastic buffering effect: the spring is designed to absorb vibration and impact during the installation and use of the battery, so as to prevent loose or damaged connection caused by mechanical stress.

Good conductivity: It is usually made of high conductivity materials, such as copper or silvered copper, to ensure smooth transmission of grounding current and reduce resistance and heating.

Suitable for different sizes and shapes: with certain elastic deformation capacity, it can adapt to batteries of different specifications and models and provide universal grounding solutions.

In practical application:

For example, in the backup battery pack of the communication base station, the grounding spring contact can guarantee the safe grounding of the battery under the complex electromagnetic environment.

In the power supply part of industrial control system, it can effectively prevent electrostatic accumulation and electromagnetic interference.

However, battery ground spring contacts have some limitations:

Fatigue life: Long-term compression and extension may lead to fatigue of the spring, reducing its elastic property and contact reliability.

Installation space requirements: due to the structure of spring, certain installation space may be required, which may pose challenges for equipment with compact space