As a professional manufacturer of flat leaf springs for electrical battery contacts, we have always taken it as our responsibility to promote innovation in power connection technology, and are committed to turning every flat leaf spring into an industry masterpiece with excellent performance and reliable quality. On the path of product development and manufacturing, we constantly explore innovation and integrate our persistent pursuit of technology into every production process.

Starting from the design source, our engineering team has conducted in-depth research on the performance requirements of electrical battery contacts, cleverly combining the structural characteristics of flat leaf springs. The flat form design not only enables efficient power transmission in limited space, but also greatly enhances the adaptability of the product, making it flexible for various compact battery systems. In order to optimize the elasticity and contact performance of the leaf spring, we use advanced mechanical simulation software to repeatedly deduce and optimize parameters such as curvature, thickness, and material distribution of the leaf spring, ensuring that each flat leaf spring can accurately fit the battery electrode, providing stable and durable contact pressure, effectively reducing contact resistance, and ensuring efficient and stable power transmission.

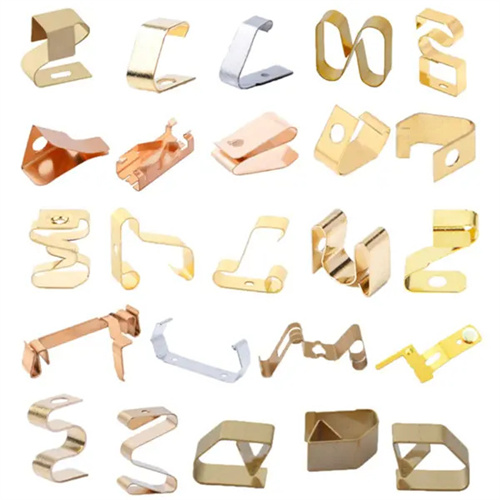

In terms of production technology, we invest a lot of resources to build intelligent and high-precision production lines. By adopting advanced stamping technology and precision machining equipment, the raw materials are accurately formed. Each stamping process undergoes strict calibration and real-time monitoring to ensure that the dimensional accuracy of the leaf spring reaches the micrometer level standard. In order to endow the flat leaf spring with better performance, we choose special alloy materials with high strength and high conductivity, and improve the material’s fatigue strength and corrosion resistance through special heat treatment processes. At the same time, we also introduce advanced surface treatment technologies, such as nickel plating and gold plating, to form a dense protective layer on the surface of the leaf spring, further enhancing its antioxidant and anti-corrosion capabilities and extending the product’s service life.

Quality is our lifeline, for which we have established a comprehensive quality control system. From strict screening of raw materials, to full process testing during the production process, to rigorous testing of finished products, every step is taken with utmost care. We are equipped with professional testing equipment, such as high-precision image measuring instruments, contact resistance testers, fatigue life testing machines, etc., to comprehensively test the dimensional accuracy, electrical performance, mechanical performance, etc. of flat leaf springs, ensuring that every product meets or even exceeds industry standards.

With excellent performance and reliable quality, our electrical battery contact flat leaf springs have been widely used in various fields such as new energy vehicles, energy storage systems, 3C electronic products, medical equipment, etc. Whether it is providing stable connections for the power battery pack of electric vehicles, assisting energy storage stations in achieving efficient energy conversion, or ensuring stable power supply in smartphones and laptops, our products have won the trust and recognition of customers with outstanding performance.

Looking ahead, we will continue to increase our research and development investment, explore new technologies and processes, and continuously optimize the performance and quality of flat leaf springs for electrical battery contacts. At the same time, we will further deepen our cooperation with customers, providing more professional services and high-quality products to meet the personalized needs of different industries and customers, and contribute more to the development of electrical connection technology.

Flat Leaf Battery Contacts offer the following outstanding features and advantages:

Large contact area: the flat blade design provides a large contact surface, which can reduce the contact resistance, ensure the stable transmission of current and reduce the heating phenomenon. For example, in high-power battery applications, energy loss and potential safety hazards caused by excessive resistance are effectively avoided.

Good flexibility and adaptability: this design has a certain flexibility, which can adapt to the dimensional change and vibration of the battery in the use process, and always maintain good contact.

Easy installation and positioning: the flat shape makes it easier to install and accurately position it during battery assembly, improving production efficiency.

Lower cost: relatively simple shape and structure, economical in material use and manufacturing process, helping to reduce overall cost.

In actual application:

In electronic equipment such as digital cameras, flat-leaf battery contacts ensure a stable power supply and support normal operation of the equipment.

Good stability and reliability play an important role in battery connection of industrial instruments.

The battery contact is an important component of the battery. It is made of materials such as copper, iron, stainless steel, etc., and its conductivity can be enhanced by electroplating CT, silver, nickel.

Battery contact is mainly used in No. 1, 2, 3, 5, 7 batteries, lighting, telephones, plush toys, electric toys and other fields. According to the different uses and performance, the material of the battery contact / shrapnel will also be different, such as the need for high physical resilience, high frequency of use, high pressure occasions, usually choose spring steel, carbon steel or high hardness stainless steel and other materials.

In addition, battery shrapnel has the characteristics of strong conductivity and good hand feel, so it is also widely used in the manufacture of some consumer electronic components. When loaded, the battery shrapnel can produce a large elastic deformation, converting the mechanical work or kinetic energy into deformation energy, and the deformation of the shrapnel disappears and returns to its original state after unloading, converting the deformation energy into mechanical work or kinetic energy. Therefore, battery shrapnel is also widely used in stamping parts, relay accessories, connector accessories, mobile phone accessories and auto parts.