We take craftsmanship as our pen and innovation as our ink, deeply cultivating the field of battery connections, focusing on the research and manufacturing of leaf shaped battery contact spring connectors. Drawing inspiration from nature, we seamlessly integrate the delicate form of leaves with precise industrial design, committed to creating battery connection solutions that combine aesthetic value and excellent performance for our customers.

At the beginning of product design, our R&D team delved into the structural mysteries of blade morphology. The unique curved surface and curvature of the blade not only give the connector an elegant appearance, but also achieve clever breakthroughs in functionality. We have conducted extensive mechanical analysis and simulation experiments to accurately optimize the spring structure, enabling the leaf shaped design to provide greater contact pressure in a limited space, ensuring a tight fit of battery contacts, effectively reducing contact resistance, and ensuring stable power transmission. Each “blade” undergoes precision stamping and forming processes, with smooth edges and no burrs. The size error is strictly controlled at the micrometer level to ensure product consistency and reliability.

In order to ensure that the leaf shaped battery contacts the spring connector with durable quality, we carefully select materials. Using high-strength and high elasticity special alloy materials, and undergoing special heat treatment processes, the material’s fatigue resistance is improved. Even after tens of thousands of cycles of stretching and pressing, it can still maintain good elasticity and contact performance. At the same time, we use advanced surface treatment technology to form a dense protective layer on the surface of the connector, effectively resisting the influence of environmental factors such as oxidation and corrosion, enabling it to operate stably under complex working conditions such as high temperature, high humidity, and high dust.

In terms of quality control, we have established a full process and high standard testing system. From raw material inspection upon arrival at the factory, to online monitoring during the production process, to performance testing of finished products, every step is strictly monitored. Through high-precision imaging measuring instruments, contact resistance testers, and other professional equipment, the dimensional accuracy, electrical performance, mechanical performance, and other aspects of the product are comprehensively tested to ensure that every leaf shaped battery contact spring connector delivered to the customer can meet or even exceed industry standards.

Nowadays, our leaf shaped battery contact spring connectors have been widely used in various fields such as new energy vehicles, smart wearable devices, medical instruments, drones, etc. In the battery management system of new energy vehicles, it ensures efficient operation of the battery pack with stable and reliable connection performance; In small electronic devices such as smart bracelets and Bluetooth earphones, their lightweight blade design saves space and helps products achieve more compact designs. We always adhere to customer demand orientation, provide customized services, optimize and improve products according to the special requirements of different industries and scenarios, and create greater value for customers. In the future, we will continue to uphold the spirit of innovation, continuously improve product quality and service levels, and contribute to the development of battery connection technology.

The Leaf Shape Battery Contact Spring offers the following features and advantages:

Good elastic deformation capacity: the blade shape design can provide uniform and moderate elasticity, ensure that the battery always maintains a stable contact pressure during installation and use, and effectively prevent poor contact.

Low resistance characteristics: help to reduce the energy loss in the transmission process of current and improve the discharge efficiency and charging speed of the battery.

Fatigue resistance: Capable of withstanding frequent compression and extension, not prone to elastic failure in long-term use, and prolonging the service life of battery contact spring.

Compact structure: the blade design occupies less space and is applicable to the battery installation environment with limited space.

In practical application:

For example, in small portable electronic devices such as bluetooth headphones, leaf-shaped battery contact springs provide reliable electrical connection in a confined space.

In the battery module of the smart watch, it can ensure the stable contact between the battery and the device without affecting the thin design of the device.

However, leaf cell contact springs have some limitations:

High manufacturing accuracy: complex blade structure requires high-precision manufacturing process and equipment, which increases the production cost.

Relatively difficult to install: due to its special shape, it requires more careful and accurate operation during installation.

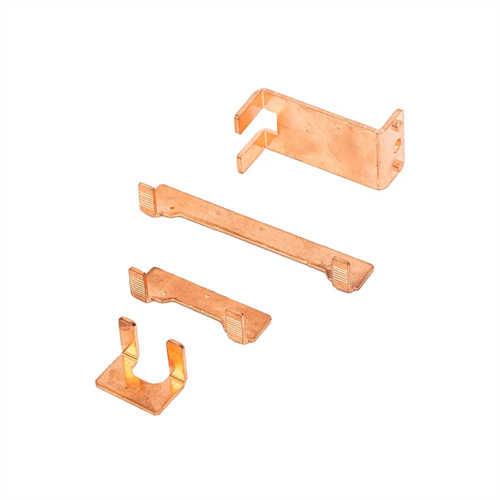

Battery contact shrapnel belongs to the category of metal stamping and electronic hardware materials, and is an important part of the battery. It is made of copper, iron, stainless steel and other materials, electroplating CT, silver, nickel, etc. Battery shrapnel is widely used in various electronic devices due to its excellent elastic properties and physical properties.

The types of battery contact / shrapnel are mainly classified according to their shape, size, material, and application. For example, it can be divided into round, square, special-shaped, etc., according to the size, it can be divided into large, medium, small, etc., and according to the material, it can be divided into copper, iron, stainless steel, etc. In addition, there are some special-purpose battery shrapnel, such as highly elastic battery shrapnel, high conductivity battery contact / shrapnel, etc.

The specific type and model of battery contact need to be selected according to different use scenarios and equipment requirements. When selecting battery shrapnel, it is necessary to consider its conductivity, elasticity, corrosion resistance, wear resistance and other factors to ensure the stability and safety of the battery.