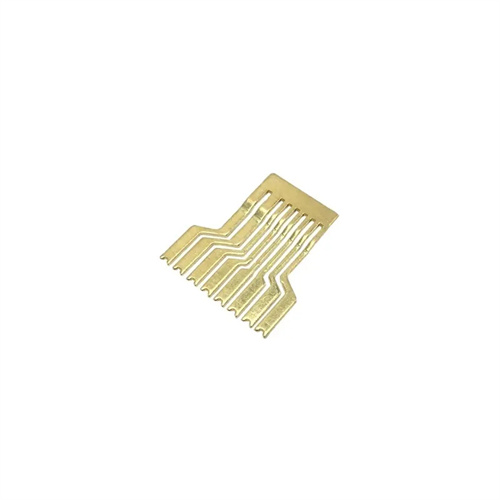

We always carry the persistence and enthusiasm for power connection technology, and are fully committed to the research and production of U-shaped copper metal stamping battery contacts. We deeply understand that the performance of battery contacts, as the core hub of power transmission, directly affects the stability and safety of equipment operation. Therefore, with an attitude of continuous improvement, we strive to make every product a benchmark in the industry.

In terms of process research and development, we have gathered top technical talents in the industry and formed a professional team to overcome numerous difficulties. The U-shaped copper metal stamping process is not an easy task. To achieve the desired forming effect, we repeatedly adjust the stamping equipment parameters and carefully design high-precision molds. Through multiple simulations and experiments, we have successfully solved the problems of deformation and rebound in the copper stamping process, enabling each U-shaped battery contact to achieve precise size standards, ensuring a tight fit with the battery electrode, minimizing contact resistance, and improving conductivity efficiency. At the same time, we have introduced advanced automated production lines to ensure production efficiency while strictly controlling product quality. Each process is monitored in real-time by an intelligent inspection system, and no minor defects are overlooked.

In terms of material selection, we adhere to the principle of selecting the best from the best, and carefully select high-purity oxygen free copper as the raw material. The excellent conductivity and good ductility of copper materials lay a solid foundation for the performance of contacts. To further enhance the environmental adaptability and service life of the product, we have carried out multiple surface treatments on the U-shaped copper metal stamping battery contacts. Through processes such as nickel plating and gold plating, not only does it enhance the corrosion resistance of the contacts, allowing them to operate stably in harsh environments such as humidity, acidity, and alkalinity, but it also significantly improves their oxidation resistance, reduces contact problems caused by oxidation, and ensures stable and reliable power transmission at all times.

With outstanding performance, our U-shaped copper metal stamped battery contacts have demonstrated their prowess in multiple fields. In the field of new energy vehicles, it provides efficient and stable power connections for the power battery system, helping vehicles drive safely; In energy storage power plants, reliable contacts ensure efficient storage and release of energy; In 3C electronic products, its compact U-shaped design meets the needs of lightweight and precision devices, providing stable battery life support for mobile phones, laptops, and other devices. The trust and praise of numerous customers are the greatest recognition of our products.

Looking ahead to the future, we will not stop moving forward. We will continue to increase research and development investment, explore new technologies and processes, and further optimize the performance of U-shaped copper metal stamping battery contacts to meet the constantly upgrading market demand. At the same time, we will deepen our cooperation with customers, listen to feedback, and provide better and more personalized power connection solutions for various industries, working together to create a better future.

The battery contact / shrapnel is an important component of the battery, which has the following characteristics:

Strong electrical conductivity: The battery contact has good conductivity, which can ensure the stable transmission of current and reduce resistance and power consumption.

Good elasticity: The battery shrapnel has good elasticity and resilience, which can return to its original state after the pressure is released, and adapt to the deformation and vibration of the battery during use.

Strong mechanical properties: The battery contact has a certain strength and toughness, which can withstand various external forces during the use of the battery, and is not easy to deform or damage.

Good corrosion resistance: Battery contact / shrapnel is usually made of stainless steel, copper and other materials with good corrosion resistance, which can adapt to corrosive factors such as chemicals or humidity in the battery working environment.

Easy installation: The battery shrapnel is usually installed on the battery conductive film, which is easy and quick to install, and can quickly complete the assembly and production of the battery.

Battery shrapnel has the characteristics of strong conductivity, good elasticity, strong mechanical properties, good corrosion resistance, easy installation, etc., and is an important part of the battery, which is widely used in various electronic devices.

The U Shape Copper Metal Stamping offers a number of important features and application advantages:

Excellent conductivity: high conductivity of copper ensures high efficiency and stability of battery current transmission and reduces energy loss and heating problems. For example, in a high-performance battery pack, this highly effective conductivity facilitates fast charging and discharging.

Precise size and shape control: the punching process can produce the U-shaped parts with accurate size and consistent shape to ensure the close and accurate contact with the positive and negative poles of the battery.

Good elasticity and recovery capacity: the contact can maintain good contact pressure during repeated plug and use to ensure the reliability of connection.

High-temperature resistance: it can still maintain the stability of its physical and electrical properties under the high temperature environment that may occur during the operation of the battery.

It is widely used in different fields:

In the field of consumer electronics, such as contacts of laptop batteries, U-shaped copper stamping parts can provide stable power connection and support normal operation of equipment.

In the new energy vehicle, the internal connection of the power battery also often adopts this kind of stamping parts to deal with the large current and complex working conditions.

However, it also has some challenges:

High material cost: copper is relatively expensive, which may increase the battery production cost.

Great processing difficulty: high requirements for stamping die and process, and high-precision equipment and technical support are required.