Innovative Design of EV Battery Pack Contacts

Our EV Battery Pack Contacts are engineered with an innovative design specifically tailored to the high – current demands of electric vehicles. We understand that in EVs, a stable and efficient power connection is crucial for optimal performance. The contacts are designed with a large – surface – area structure to minimize electrical resistance and facilitate the smooth flow of high currents. This increased contact area reduces heat generation during power transfer, ensuring the safety and longevity of the battery pack and related components.

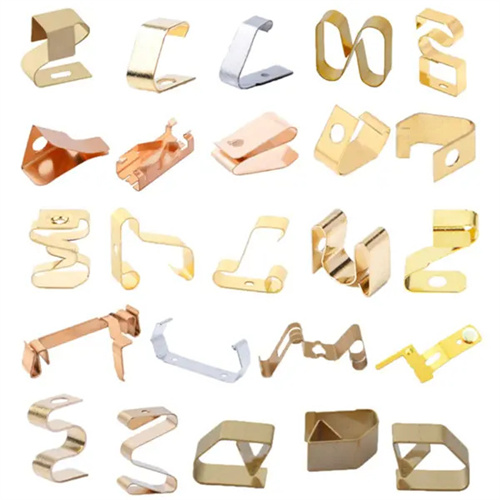

The shape and layout of the contacts are optimized to fit seamlessly within the compact space of EV battery packs. We incorporate features such as interlocking mechanisms and precise alignment guides to ensure a secure connection that can withstand the vibrations and mechanical stresses experienced during vehicle operation. Additionally, the design allows for easy installation and maintenance, reducing downtime during battery pack assembly and service. This innovative approach to design makes our Battery Contacts a reliable choice for electric vehicle manufacturers.

Superior Material Selection for Battery Contacts

We take great care in selecting materials for our EV Battery Pack Contacts to ensure superior performance. High – conductivity metals, such as copper and its alloys, are the primary choice for the contact components. Copper offers excellent electrical conductivity, enabling efficient transfer of high currents with minimal power loss. To further enhance conductivity and prevent oxidation, we apply advanced surface treatments, such as silver or gold plating.

For the insulating and protective parts of the contacts, we use high – quality engineering plastics with excellent heat resistance, flame retardancy, and electrical insulation properties. These materials can withstand the high temperatures generated by high – current flow and protect against electrical short – circuits. The combination of these carefully selected materials not only ensures the reliable operation of the battery contacts but also enhances their durability and safety in the demanding environment of electric vehicles.

Reliable Performance in High-Current Scenarios

Our EV Battery Pack Contacts deliver reliable performance in high – current applications. The low electrical resistance of the contacts ensures efficient power transfer from the battery pack to the vehicle’s powertrain and other electrical systems. This efficiency contributes to improved vehicle range and performance, as less energy is wasted as heat during the current transfer process.

These contacts are also designed to withstand the harsh operating conditions of electric vehicles. They can endure repeated cycles of high – current flow without degradation, maintaining a stable electrical connection over time. The materials and construction of the contacts resist corrosion, wear, and mechanical fatigue, ensuring long – term reliability. Whether in stop – and – go city traffic or high – speed highway driving, our Battery Contacts provide a consistent and secure connection for the high – current needs of electric vehicles.

Meticulous Manufacturing Process of Battery Contacts

The production of our EV Battery Pack Contacts involves a meticulous manufacturing process. We start by sourcing the highest – quality raw materials from trusted suppliers, ensuring that they meet our strict standards for electrical conductivity, mechanical strength, and safety. The manufacturing process begins with precision machining and stamping to shape the contact components with extreme accuracy.

After shaping, the components undergo a series of surface treatments and assembly processes. Each step is closely monitored by our quality control team, using advanced inspection equipment to check for dimensional accuracy, surface finish, and electrical conductivity. The final assembled contacts are then subjected to rigorous testing, including high – current load testing, temperature cycling, and vibration testing. Only contacts that pass all these tests are approved for use in electric vehicle battery packs, guaranteeing that our customers receive products of the highest quality.

Diverse Applications in Electric Vehicles

Our EV Battery Pack Contacts find diverse applications within electric vehicles. They are essential for connecting the individual battery cells within a battery pack, ensuring a balanced and efficient flow of current. In the connection between the battery pack and the vehicle’s motor controller, our contacts enable the high – power transfer required for propulsion.

These contacts also play a crucial role in the charging system of electric vehicles. Whether it’s a slow – charging household connection or a high – speed DC fast – charging station, our Battery Contacts ensure a reliable and safe connection for energy transfer. Additionally, they are used in the battery management system, facilitating communication and power distribution between the battery pack and other vehicle systems. From the core power delivery to various auxiliary functions, our contacts are integral to the operation of electric vehicles.

Comprehensive Customer Support for Battery Contacts

We are committed to providing comprehensive customer support for our EV Battery Pack Contacts. Our team of experts is available to assist customers throughout the entire process, from the initial product selection to after – sales service. We offer detailed technical advice on choosing the right type of contact for specific electric vehicle models, taking into account factors such as battery capacity, voltage requirements, and vehicle design.

In case of any issues or concerns, our responsive after – sales service team is ready to provide prompt solutions. Whether it’s a question about product performance, a need for replacement parts, or assistance with installation, we strive to ensure that our customers are completely satisfied with our products and services. We also welcome feedback from our customers to continuously improve our offerings, aiming to build long – term relationships based on trust, reliability, and exceptional support in the electric vehicle industry.