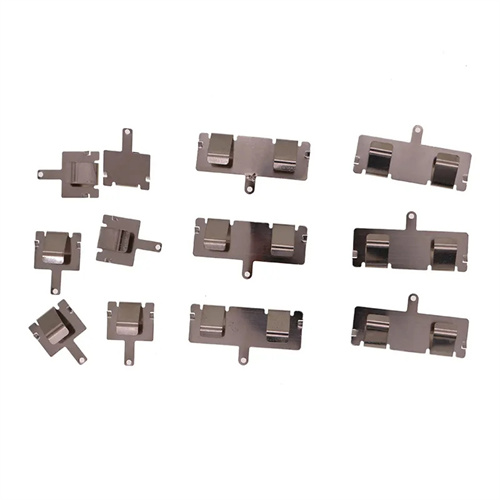

Custom Sizes Electrical Contacts feature the following:

Precise adaptability: provide accurate matching dimensions according to the unique space and structure requirements of specific equipment or system, realize perfect installation and connection, and avoid installation difficulties or performance loss caused by unmatched dimensions.

Optimized performance: since the size is customized according to the specific current load, voltage requirements and contact resistance standards, the conductive performance and reliability of the electrical contact can be optimized to the maximum extent, and the overall efficiency and stability of the equipment can be improved.

Personalized design: in addition to size customization, personalized design can be carried out in shape, contact mode and material selection to meet the requirements of special working environment, mechanical stress and temperature conditions.

Improving space utilization: in equipment with limited space, customized electric contacts can make full use of every inch of space to realize more compact and efficient circuit layout.

Enhanced compatibility: Seamless compatibility with specific connectors, sockets, or other mating components to ensure integrity and coordination throughout the circuit system.

Custom sized electrical contacts are widely used in many areas, such as:

In aerospace, precise sized electrical contacts are provided for special electronics on satellites and aircraft to adapt to extreme space environments and stringent weight limitations.

In the manufacturing of medical equipment, according to the internal structure of different medical instruments, customized electrical contacts can ensure the high-precision and high-reliability operation of the equipment.

In the high-end industrial automation equipment, it meets the special requirements for the size and performance of the electrical contact in the complex mechanical system, and improves the production efficiency and product quality.

On the internal circuit board of a new smart phone, the customized electric contact can realize efficient power transmission and signal connection in a narrow space, improving the performance and stability of the mobile phone; In a precision medical imaging device, customized electrical contacts perfectly match the unique structure of the device, ensuring the accuracy and reliability of image generation.

There are various types of electronic contact pieces, and the following are some common classification methods:

According to the structural form, it can be divided into single electrical contact pieces, double contact pieces, and spring contact pieces.

According to the material, it can be divided into copper contact pieces, silver contact pieces, stainless steel contact pieces, etc. Electronic contact pieces made of different materials have different electrical and physical properties, such as conductivity, wear resistance, corrosion resistance, etc.

According to the usage environment, it can be divided into sealed electrical contact pieces, dust-proof contact pieces, high-temperature resistant electrical contact pieces, etc. Electronic contact pads with different usage environments will consider different factors in their design and manufacturing to meet specific usage requirements.

According to their functions, they can be divided into fixed contact pieces and movable contact pieces. Fixed electrical contact pieces are usually used to fix various electrical components in a circuit, while movable contact pieces are usually used to achieve circuit state transitions, such as switches, relays, etc.

Overall, the types of electronic contact pieces are very diverse, and different types of electronic contact pieces can be selected according to different needs.

As a manufacturer of custom sized electrical contacts, we always adhere to the service tenet of “unlimited size, demand-oriented”, and deeply understand the special requirements of different industries and equipment for the size of electrical contacts. From micrometer level precision specifications to special sizes required for large equipment, we tailor precise and adaptable electrical contact solutions for our customers based on professional technology and rich experience.

At the beginning of customized services, our professional team will have in-depth communication with customers to gain a detailed understanding of their equipment characteristics, installation space, performance requirements, and other key information. Whether it is the strict requirements for miniaturization and integration of contacts in electronic devices, or the special requirements for large-sized and high-strength contacts in industrial machinery, we will provide professional size design suggestions based on the parameters provided by customers, combined with industry standards and practical application scenarios. We are well aware that precise dimensions not only affect the installation adaptability of contacts, but also directly impact their electrical performance and service life. Therefore, every dimension data has been carefully considered and rigorously verified.

To achieve precise customization, we have built a strong R&D and production system. In the research and development process, we use advanced computer-aided design (CAD) and computer-aided engineering (CAE) technologies to transform customer requirements into three-dimensional design models, and through simulation, verify the performance of the contacts under different working conditions in advance. At the same time, we have a rich material library, covering various materials such as high conductivity copper alloys, corrosion-resistant stainless steel, low resistance precious metals, etc., which can be accurately matched according to size and performance requirements. In terms of production and manufacturing, we have introduced internationally leading CNC machining equipment, precision stamping molds, and automated production lines to ensure that whether it is a fine size as small as a hair or a large specification of several meters in length and width, the size error can be strictly controlled at the micrometer level, achieving perfect restoration of design drawings.

Quality control runs through the entire process of producing custom sized electrical contacts. We have established a complete quality traceability system, from strict inspection of raw materials upon arrival at the factory, to real-time monitoring during the production process, and to full-size and full performance testing of finished products, with strict standards implemented at every stage. We are equipped with high-precision image measuring instruments, coordinate measuring machines and other professional testing equipment to conduct comprehensive testing of the length, width, thickness, curvature and other dimensional parameters of the contacts. At the same time, we combine electrical performance testing such as contact resistance testing and fatigue life testing to ensure product quality is foolproof.

With excellent customization capabilities and reliable product quality, our customized size electrical contacts have been widely used in various fields such as communication equipment, aerospace, new energy vehicles, industrial automation, etc. The ultra large electrical contacts customized for a certain communication base station perfectly adapt to its complex equipment structure, ensuring stable signal transmission; The small-sized contacts designed for microsensors achieve efficient electrical connections with precise specifications. In the future, we will continue to deepen our expertise in the field of customization, continuously improve our technical strength, and meet the diverse needs of our customers with more professional services, becoming the industry benchmark in the field of customized size electrical contacts.