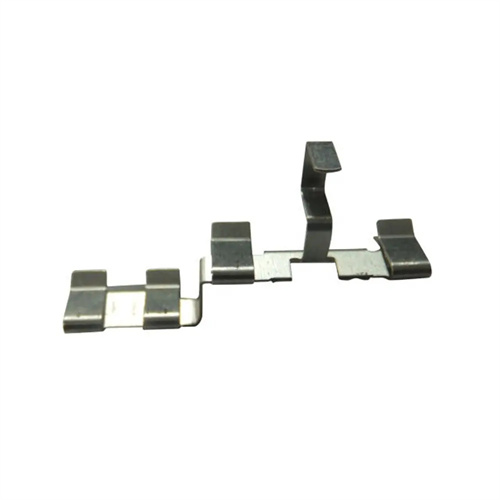

Stainless Steel Electrical Contacts

Electronic contact pieces are a type of electronic component mainly used to connect various electrical components in a circuit, allowing current to flow between these components. Electrical contact pieces are usually made of metal and have good conductivity and corrosion resistance. They come in various forms, including but not limited to the following:

Contact piece: It is a long strip of metal, usually made of materials such as copper, nickel, and iron. It has good conductivity and corrosion resistance, and is widely used in various electrical equipment, such as relays, contactors, switches, etc.

Spring plate: also known as “spring plate”, is a metal plate that can be bent, usually made of materials such as stainless steel or nickel alloy. It has good elasticity and conductivity, and is widely used in various electrical components such as connectors, sockets, and inserts.

Insert: It is a type of insertable metal sheet, usually made of materials such as copper and iron. It is widely used in various electrical components such as plugs and sockets to connect and disconnect circuits.

Electronic contact pieces play a very important role in circuits, as they can control the flow path of current, achieve on/off control of circuits, and convert circuit states. Meanwhile, the performance and quality of electrical contact pieces also have a significant impact on the performance and stability of the entire circuit. Therefore, when selecting and using electrical contact pads, it is necessary to choose appropriate specifications and models based on actual application needs and conditions, and pay attention to their installation and maintenance.

Stainless Steel Electrical Contacts have the following features:

Good strength and hardness: stainless steel has high strength and hardness, can bear large mechanical pressure and impact force, is not easy to deform or damage, and can maintain stable contact performance under severe working conditions.

Excellent corrosion resistance: it has strong corrosion resistance to a variety of chemicals and environmental conditions, and can effectively prevent rust and corrosion in the presence of wet, corrosive gases or liquids, thus extending the service life.

High temperature stability: it can maintain its mechanical and electrical properties at high temperature, and it is applicable to electrical equipment in high temperature working environment.

Good abrasion resistance: Capable of withstanding frequent friction and abrasion, reducing poor contact caused by abrasion.

Cost effectiveness: compared with some expensive metals, stainless steel price is relatively reasonable, and it has a certain cost advantage while guaranteeing the performance.

However, stainless steel electrical contacts have some limitations, such as their relatively lower conductivity than metals such as silver and copper.

Stainless steel electrical contacts are commonly used in the following scenes: in industrial automation control systems, they are used for the connection of various sensors and actuators to adapt to harsh industrial environments. In outdoor electrical equipment, such as street lamp control system, power distribution box, etc., it can resist weathering and erosion of corrosive substances. In electrical equipment of petrochemical industry, stainless steel electrical contact can work reliably in corrosive medium environment; In some connectors that require frequent plugging and unplugging, abrasion resistance ensures long-term stability.

As a stainless steel electrical contact manufacturer deeply involved in the field of electrical connections, we always adhere to the concept of “building on quality and seeking breakthroughs through innovation”, and are committed to providing global customers with high-performance electrical contact solutions. We are well aware that in the operation of electrical equipment, contacts are not only the hub of power transmission, but also the key to ensuring system stability and safety. The characteristics of stainless steel materials give contacts unique advantages in dealing with complex working conditions. We take this as our core and constantly explore the technological boundaries.

In the product development process, our professional team conducts in-depth research on the electrical contact requirements of different application scenarios. We carefully select suitable stainless steel materials for harsh environments such as high temperature, high humidity, and strong corrosion. Through composition optimization and ratio testing, we ensure the conductivity of the material while maximizing its corrosion resistance and wear resistance. With the help of advanced finite element analysis and simulation technology, we have finely designed the structure of the contacts. From the shape, curvature, to surface texture of the contacts, every detail has been carefully considered to ensure that the contact resistance can be reduced during the current transmission process, and the arc energy can be effectively dispersed to reduce contact losses.

In the manufacturing process, we have created an intelligent and high-precision production system. We introduce internationally leading precision machining equipment and use advanced processes such as laser cutting and CNC stamping to accurately process stainless steel raw materials into electrical contacts that meet strict standards. To further enhance product performance, we have independently developed a special surface treatment technology that forms a dense protective layer on the contact surface through processes such as nanoscale polishing and passivation. This not only enhances its antioxidant capacity, but also significantly reduces surface roughness and optimizes conductivity. Each production process is equipped with an intelligent monitoring system to track production data in real-time, ensuring the stability and consistency of product quality.

Quality control is of utmost importance in our production process. We have established a full lifecycle quality traceability system, which implements strict testing standards at every stage from component testing and mechanical performance testing of raw materials entering the factory, to dimensional accuracy verification and electrical performance sampling during the production process, to high and low temperature cycling testing and salt spray corrosion testing of finished products. Our professional laboratory is equipped with high-end testing equipment such as contact resistance tester, spectrometer, metallographic microscope, etc., to conduct comprehensive and multi-dimensional testing of the various properties of the contacts. Only products that have passed all rigorous tests can be labeled as qualified and delivered to customers.

With excellent performance and reliable quality, our stainless steel electrical contacts have been widely used in various fields such as new energy vehicles, offshore wind power, petrochemicals, medical equipment, etc. In offshore wind power equipment, our contacts are not afraid of high salt spray environments, ensuring stable power transmission; In medical equipment, its low resistance and high stability characteristics help the equipment operate accurately. In the future, we will continue to increase research and development investment, explore new materials and processes, continuously optimize product performance, provide solid guarantees for electrical connections in various industries with higher quality stainless steel electrical contacts, and promote the sustainable development of electrical technology.