U-Shape Metal Spring Clip Fourslide Multislide Stamping Manufacturer

Fourslide Multi slide Stamping are both commonly used metal stamping equipment, widely used in metal stamping and forming processes in industries such as automobiles, electronics, home appliances, and communications.

Fourslide stamping is a four column stamping machine, mainly composed of four guide pillars, sliders, worktable, and press body. It uses the up and down reciprocating motion of the slider to stamp and shape the metal sheet. This type of equipment has a large pressure and stroke, and can process various large metal parts.

Multi slide stamping is a multi-station stamping machine that can simultaneously complete multiple metal stamping and forming processes of different shapes and sizes. It usually consists of multiple sliders, molds, and workbenches, each of which can be independently controlled to achieve stamping and forming of different shapes and sizes. Multi slide has the characteristics of high efficiency, high precision, and high automation, which can greatly improve production efficiency and product quality.

Overall, Fourslide Multi slide stamping are important metal stamping equipment that can be selected according to different production needs.

U-Shape Metal Spring Clip offers the following features and advantages:

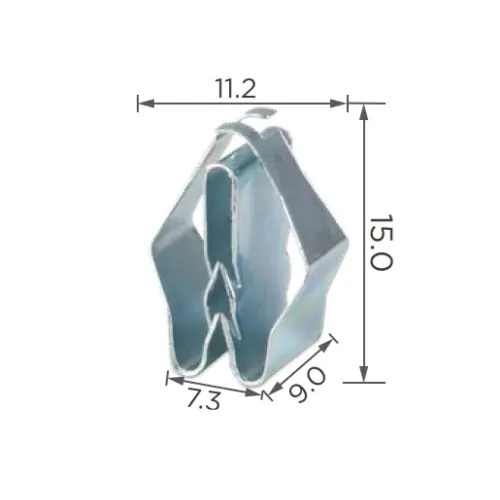

Unique structure design: U-shaped structure provides good mechanical support for clamping, making clamping more stable.

Strong clamping force: due to the elastic action of the spring, it can generate a large clamping force to tightly fix the object.

Easy to operate: simple shape makes it easy to use without complicated operation steps.

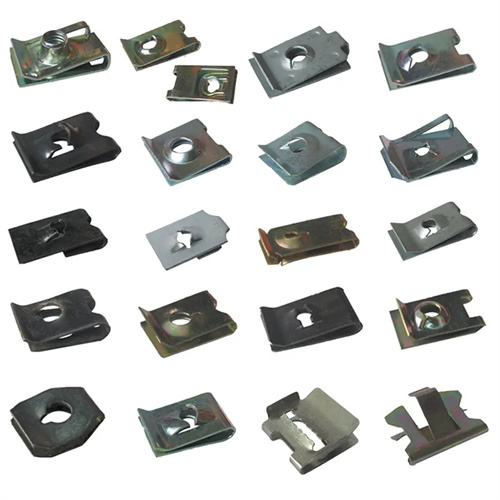

Good versatility: applicable to clamping various shapes and sizes of objects, with a wide range of applications.

Cost effectiveness: the relatively simple structure and manufacturing process make the cost relatively low and have high cost performance.

In office supplies, it can be used to fix documents and paper. It can hold clothes, bags and other articles in family life. However, U-shaped metal spring clips have some limitations: limited clamping range: they may not provide ideal clamping for oversized or undersized objects.

In the field of metal stamping parts manufacturing, we focus on the research and production of U-shaped metal spring clips with a deep understanding and proficient application of Fourslide and Multislide stamping technologies. With professional strength, we provide high-precision and high-performance high-quality products for customers in various industries.

Although U-shaped metal spring clips may seem structurally simple, they play an indispensable role in many fields such as mechanical assembly, electronic equipment, and the automotive industry. From the quick connection and fixation of components to the orderly organization and protection of circuits, their elastic clamping force and structural stability directly affect the operational efficiency and reliability of equipment. However, traditional stamping processes often face challenges in producing U-shaped metal spring clips, such as insufficient forming accuracy, rapid elastic attenuation, and difficulty in achieving complex details. And relying on Fourslide and Multislide stamping technology, we have successfully broken through these technological barriers and brought innovation to the manufacturing of U-shaped metal spring clips.

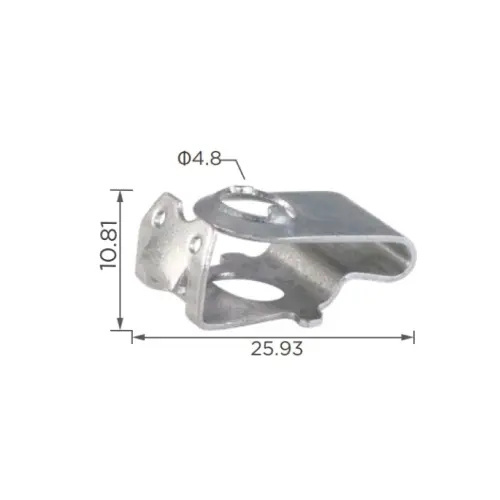

Fourslide stamping technology, with its four directional slider cooperative operation, can accurately shape metal materials into ideal U-shaped structures and finely process details. During the production process, the four directional sliders cooperate with each other to bend and form metal wires or plates at multiple angles and levels. Whether it is the curvature of the U-shaped clamping arm, the precise size of the bayonet, or the shaping of special reinforcement structures, high-precision machining at the millimeter level can be achieved by precisely controlling the slider movement trajectory and pressure parameters. This enables each U-shaped metal spring clip to have stable and strong clamping force, maintaining good elasticity and structural integrity even in long-term use or harsh environments.

Multislide stamping technology adopts an efficient mode of continuous stamping with multiple sliders, greatly improving the production efficiency and consistency of U-shaped metal spring clips. Under multi station collaborative operation, the entire process from metal material feeding, stamping and forming to cutting is seamless and highly automated. This not only enables quick response to customers’ large-scale order demands, but also ensures that the U-shaped metal spring clips produced in bulk maintain a high degree of uniformity in key indicators such as dimensional accuracy and elasticity, meeting customers’ strict requirements for product stability and standardization. In scenarios where there is a high demand for U-shaped metal spring clips, such as automotive parts assembly and home appliance production, Multislide technology, with its efficient and stable production capacity, has become a solid support for us to meet customer delivery needs.

We always regard product quality as the foundation of enterprise development. Starting from the raw material procurement process, we strictly screen high-quality metal materials with high strength, fatigue resistance, and corrosion resistance to ensure that every U-shaped metal spring clip has good mechanical properties and environmental adaptability. During the production process, advanced sensors and monitoring systems are used to monitor stamping parameters in real-time and strictly control each process; Before leaving the factory, the clamping force and fatigue life of the spring clamp are tested by professional mechanical testing equipment, and the dimensional accuracy is checked by precision measuring instruments. Only products that have undergone rigorous quality inspection throughout the entire process can be delivered to customers.

With the profound accumulation of Fourslide and Multislide stamping technology, as well as the relentless pursuit of quality, our U-shaped metal spring clips have been widely used in many industries and highly recognized by customers. In the future, we will continue to explore technological innovation, optimize production processes, and work hand in hand with customers to contribute more to the development of metal stamping parts manufacturing with higher quality products and services.