Fourslide Multislide Stamping is a metal stamping process that uses a four column stamping machine for stamping and forming metal parts. This process is mainly suitable for metal stamping and forming processing in industries such as automobiles, electronics, home appliances, and communications, and has the characteristics of high efficiency, high precision, and high automation.

Fourslide Multislide Stamping equipment usually consists of four guide pillars, sliders, workbenches, and a press body. The stamping and forming of metal sheets are achieved through the reciprocating motion of the sliders. This process can process metal parts of various shapes and sizes, such as automotive components, electronic components, household appliance casings, etc., and has broad application prospects.

Compared with other metal stamping processes, Fourslide Multislide Stamping has higher accuracy and smaller error range, which can better meet the processing needs of high-precision products. In addition, the automation level of Fourslide Stamping equipment is relatively high, which can significantly improve production efficiency and product quality, reduce errors and safety hazards caused by manual operations.

Overall, Fourslide Multislide Stamping is an efficient, high-precision, and highly automated metal stamping process with broad application prospects and market demand.

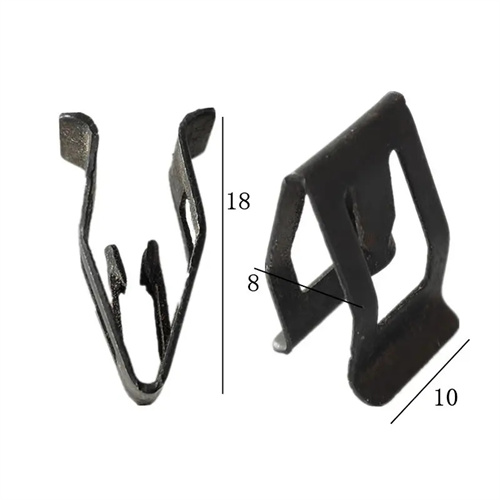

Fourslide Multislide Flat Clips offer the following features and advantages:

Flat design saves space: Its flat shape helps to use in narrow space without occupying too much installation space, especially for compact equipment or components inside.

Uniform clamping distribution: four-slider and multi-slider structure can ensure uniform clamping force distribution on the whole flat surface, so as to make the clamped object bear more balanced force and reduce the risk of local deformation or damage.

High-precision clamping and positioning: High-precision positioning and fixing of the clamped object can be realized, which is very beneficial for the operation requiring precise assembly and alignment.

Good stability: provide stable clamping effect during operation and not easy to be loosened due to vibration or external force.

Material diversity: different materials can be selected according to specific application requirements, such as stainless steel, aluminum alloy, etc., to meet the requirements of strength, corrosion resistance, etc.

In actual application:

For example, in the wiring fixation of electronic equipment, the flat clamp can firmly fix the wiring in a limited space to ensure the stability of signal transmission.

In the assembly process of precision instrument, it is used to fix small flat parts to ensure the assembly accuracy.

In the field of metal stamping products, we focus on Fourslide and Multislide stamping processes, deeply cultivate the research and production of flat clamps, and are committed to creating high-quality products with excellent precision and stable performance for our customers.

Although flat clamps have a simple structure, they play a crucial role in industries such as electronics, automotive, and home appliances. From circuit fixation to component connection, their quality directly affects the stability of equipment operation. Traditional stamping methods often face challenges such as insufficient accuracy and poor consistency in mass production when producing flat clamps. However, we have successfully overcome these bottlenecks by relying on Fourslide and Multislide stamping technologies.

Fourslide stamping technology, with its four directional slider cooperative operation, endows flat clamps with complex and precise forming capabilities. During the production process, the four directional sliders work closely together, allowing for multi angle and multi-level bending and shaping of metal sheets. Even for flat clamps with special slots and irregular notches, we can ensure that every detail of the clamp meets the design standards by precisely controlling the slider movement trajectory and pressure parameters, achieving stable clamping force and adaptability, and meeting the demanding requirements of micro circuit fixation and precision instrument component connection in electronic devices.

Multislide stamping technology provides a guarantee for the large-scale production of flat clamps through the efficient mode of continuous stamping with multiple sliders. Under the collaborative operation of multiple workstations, metal sheets can be fed, stamped, and cut in one go, which not only greatly improves production efficiency, but also ensures high uniformity in size accuracy and shape specifications of batch produced flat clamps. In scenarios such as home appliance manufacturing and automotive interior assembly that require the extensive use of flat clips, Multislide technology can quickly respond to large-scale order demands and help customers shorten production cycles with stable quality output.

To ensure product quality, we have established a full process quality control system. On the raw material side, strict screening of high-strength and corrosion-resistant metal plates such as stainless steel and aluminum alloy is carried out to control quality from the source; In the production process, high-precision CNC stamping equipment and real-time monitoring systems are introduced to dynamically control parameters such as stamping pressure and forming temperature; In the final product inspection stage, professional equipment such as optical imaging measuring instruments and mechanical performance testing machines are used to comprehensively test the dimensional accuracy, clamping force, fatigue life and other indicators of flat clamps. Only products that have passed rigorous inspections at all levels will be delivered to customers.

With the deep application of Fourslide and Multislide stamping technology, as well as the ultimate pursuit of quality, our flat clamps have been widely used by many well-known domestic and foreign enterprises. In the future, we will continue to explore technological innovation, optimize production processes, meet customers’ constantly upgrading needs with higher quality products and services, and continue to lead the industry development in the field of metal stamping flat clamps.