Fourslide Multislide Stamping is a metal stamping process that uses a four column stamping machine to stamp and shape metal sheets. This process processes metal sheets into various shapes and sizes of parts through the reciprocating motion of four sliders, and is widely used in the metal stamping and forming process of industries such as automobiles, electronics, home appliances, and communications.

Fourslide Multislide Stamping has the characteristics of high efficiency, precision, and automation, which can significantly improve production efficiency and product quality. Meanwhile, due to its four column structure, it has a large workspace and flexibility, which can adapt to the stamping and forming of metal sheets of different shapes and sizes.

It should be noted that Fourslide Multislide Stamping requires the use of professional stamping equipment and molds, and requires high skills and experience from operators. In the production process, it is necessary to strictly control the process parameters and mold accuracy to ensure the stability of production and the reliability of product quality.

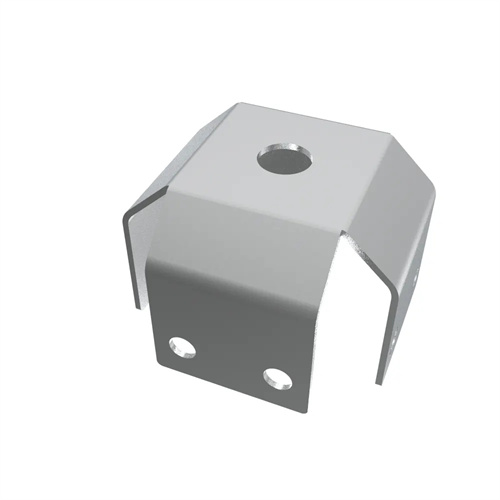

Fourslide Multislide Clip has the following outstanding features and advantages:

Stable clamping force: the design of four-slider and multi-slider enables the chuck to provide uniform and strong clamping force to ensure the stable fixation of the clamped object.

High-precision positioning: High-precision positioning of the clamped object can be realized to reduce the deviation, which is applicable to the application scenarios with high requirements for position accuracy.

Flexibility: according to different clamping requirements, the clamping size and force of the clamping piece can be changed through the adjustment of the slider.

Durability: It is usually made of high-strength materials and has excellent abrasion resistance and fatigue resistance through strict machining process, so it can be used for a long time.

Diversified application: applicable to various industries and fields, such as electronic equipment manufacturing, mechanical assembly, auto parts processing, etc.

In actual application:

For example, in the production of electronic circuit boards, it is used to fix tiny electronic components to ensure the accuracy and stability of assembly.

In the automobile production line, various parts can be clamped for installation and welding.

On the track of metal product manufacturing, we focus on the production of metal stamping clamps with a deep understanding and innovative application of Fourslide and Multislide stamping technologies, providing customers in various industries with high-quality products that combine functionality and reliability.

Although metal stamping clamps may seem small and compact, they play a crucial role in mechanical assembly, electronic equipment, automotive industry, and other fields, undertaking important functions such as connection, fixation, and clamping. Traditional stamping processes often encounter problems such as difficulty in forming, low efficiency, and low yield when dealing with complex shapes and high-precision requirements of clamping parts. And our introduction of Fourslide and Multislide stamping technology has brought revolutionary breakthroughs to the production of metal clips.

Fourslide stamping technology, with its four directional slider cooperative forming characteristics, can shape metal sheets or wires into various complex and precise clamp shapes. Whether it is micro clamps used for circuit fixing in electronic devices or irregular clamps used for component connection in mechanical devices, we can achieve multi angle and multi-level bending and forming by accurately controlling the motion trajectory and pressure parameters of the four-way slider, ensuring that each clamp can perfectly meet the design requirements, with stable clamping force and excellent structural strength.

Multislide stamping technology, relying on the continuous stamping advantage of multiple sliders, greatly improves the production efficiency and consistency of metal clamps. In the production process, multiple sliders are used to sequentially punch, cut, and shape metal materials according to a preset program, and the entire process is completed in one go. This not only significantly shortens the production cycle, but also ensures that the mass-produced clamps maintain a high degree of uniformity in size accuracy and shape specifications. Multislide technology can quickly respond to customers’ large-scale order demands and win their trust with stable quality output in scenarios where a large number of clips are required for automotive interior assembly, household appliance component fixation, and other applications.

We always regard product quality as the foundation of our foundation. Starting from the raw material procurement process, we strictly screen high-quality metal materials such as stainless steel, carbon steel, aluminum alloy, etc. to ensure that they have good mechanical properties and corrosion resistance. In the production process, high-precision CNC stamping equipment and advanced detection instruments are equipped to monitor and collect real-time data for each process. By using a visual inspection system to accurately measure the appearance and dimensions of the clamping parts, and using mechanical testing equipment to strictly inspect the clamping force and fatigue resistance of the clamping parts, only metal stamping clamping parts that have undergone rigorous quality inspection throughout the entire process can enter the final delivery stage.

With the unique advantages of Fourslide and Multislide stamping technology, as well as our relentless pursuit of quality, our metal stamping clamps have been widely used in many industries worldwide. In the future, we will continue to explore technological innovation, optimize production processes, and work hand in hand with customers to embark on a new journey of development with higher quality products and more thoughtful services, injecting new vitality into the field of metal product manufacturing.