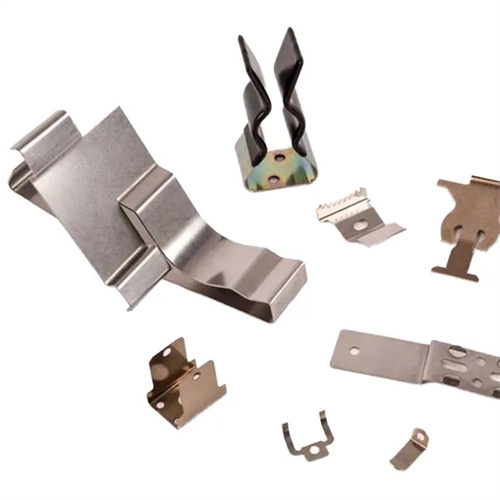

Fourslide Multislide Stamping is a metal stamping process that uses a four column stamping machine for stamping and forming. This process is mainly used for the processing of small metal parts, such as metal parts in industries such as automobiles, electronics, home appliances, and communications.The characteristic of Fourslide Multislide Stamping is the use of a four column stamping machine, which has high accuracy and stability, and can complete various complex shapes and sizes of metal stamping and forming processing. Meanwhile, due to its high processing efficiency, it can significantly improve production efficiency and reduce production costs.

In addition, Fourslide Multislide Stamping can also adopt automation technology to achieve automated feeding, processing, and discharging, further improving production efficiency and product quality. Therefore, Fourslide Multislide Stamping has been widely used in the metal processing industry.

Overall, Fourslide Stamping is an efficient, high-precision, and highly automated metal stamping process suitable for the processing and manufacturing of small metal parts.

Fourslide Multislide Retaining Spring offers the following features and advantages:

Precise fixation performance: the four-slider and multi-slider design can realize more accurate and stable fixation of the object and ensure that the object is not loosened under various working conditions.

Good elasticity and resilience: the material and structure of the spring enable it to have excellent elasticity, withstand multiple stretching and compression, maintain the fixing effect and extend the service life.

It can adapt to complex shapes: it can be customized according to the shape of the object to be fixed to adapt to different geometric shapes and size requirements.

Wear-resistance: after special treatment or selection of wear-resistant materials, it can reduce abrasion in frequent use and ensure long-term reliable fixing function.

Uniform stress distribution: four-slider and multi-slider structure helps to achieve more uniform stress distribution and avoid damage caused by local stress concentration.

In actual application:

For example, in the field of mechanical manufacturing, it is used to fix precision parts to ensure position accuracy during machining and operation.

In the automotive industry, it can be used to fix interior parts or some key mechanical components.

In the field of spring manufacturing, we focus on maintaining the research and production of springs with Fourslide and Multislide stamping technology, providing excellent performance and reliable quality products for various industries.

Although the spring is small, it is an indispensable key component in many devices and machinery, and its performance directly affects the stability and service life of the equipment. Under traditional manufacturing processes, it is difficult to achieve ideal accuracy, consistency, and production efficiency of springs. And we introduced Fourslide and Multislide stamping technology, completely changing this situation.

Fourslide stamping technology provides an excellent solution for maintaining the complex shape of springs through its unique four-way slider forming method. During the production process, the four directional sliders work together to accurately bend and shape metal materials from multiple angles and directions. Whether it is a torsion spring with a special angle or a waveform spring with a complex shape, we can accurately shape the metal wire into the desired shape through Fourslide technology, ensuring that every bend of the spring meets strict design standards, thereby achieving excellent elastic performance and reliable fixing function.

Multislide stamping technology significantly improves the production efficiency of retaining springs while ensuring accuracy. The continuous stamping operation with multiple sliders allows metal materials to complete multiple processes on the same equipment, from material feeding to forming and cutting in one go. This efficient production mode not only shortens the delivery cycle, but also ensures a high degree of consistency in the mass-produced springs, meeting customers’ demands for large-scale and standardized products. Multislide technology has played a significant role in the production of automotive engine valve springs, contact springs for electronic devices, and other products, providing each retaining spring with stable elasticity and long-lasting durability.

To ensure product quality, we have established a strict quality control system. Starting from the selection of raw materials, we only use high-quality metal materials such as spring steel and stainless steel to ensure that each metal wire has good toughness and fatigue resistance. In the production process, we use advanced sensors and monitoring equipment to monitor various parameters in real-time during the stamping process. Once any abnormalities are detected, they are immediately adjusted to nip quality hazards in the bud. After the product is formed, we will also conduct comprehensive testing on the spring’s elasticity, fatigue life, dimensional accuracy, etc. through professional testing instruments. Only by holding the spring through layers of testing will it be delivered to customers.

With Fourslide and Multislide stamping technology, as well as a persistent pursuit of quality, our produced retaining springs are widely used in various fields such as automotive, electronics, aerospace, and have gained unanimous recognition from customers. In the future, we will continue to deepen our technological innovation, optimize production processes, and provide customers with higher quality and more efficient spring products and services.