Metallic V Shape Flat Spring Fasteners are a wide variety of industrial applications, and their unique V-shaped design provides exceptional flexibility and fastening performance.

1、 Product features

V-shaped design: This fastener adopts V-shaped flat spring structure, which can provide uniform clamping force and ensure the stability and reliability of connection.

Excellent elasticity: metal spring materials give good elasticity to fasteners, which can adapt to parts of different sizes and shapes to achieve close fit.

Strong corrosion resistance: it is usually made of stainless steel, copper alloy and other corrosion resistant materials, which can be used for a long time under severe environment without being damaged.

Simple and convenient installation: reasonable design, simple and fast installation process, without complicated tools and equipment.

2、 Field of application

Metal V Shape Flat Springits outstanding performance has been widely used in the following areas:

Automotive manufacturing: used to fix auto parts, such as engine hood, doors, seats, etc., to ensure the safety and comfort of the vehicle.

Electronic equipment: in electronic equipment, this kind of fastener can be used to fix key parts such as circuit board and battery to prevent looseness and falling off.

Mechanical equipment: in mechanical equipment, they can be used to connect and fix transmission parts, support structures, etc. to ensure the normal operation of machinery.

Construction Industry: In the construction sector, Metal V Shape Flat Springbuilders can be used to secure infrastructure such as pipes and wires, improving the safety and durability of buildings.

The metal V-clip fastener is a special clamp that is mainly characterized by having a V-shaped structure, which helps to provide uniform clamping force in multiple directions. This type of fixture is usually made of metal, which has high strength and durability, so it can withstand large clamping forces and remain stable for a long time.

In practical applications, metal V-clamps are often used where precise positioning and stable clamping are required. For example, in machining, it can be used to fix the workpiece to ensure that the workpiece remains stable during machining, thereby improving machining accuracy and efficiency. Metal V-clip fasteners also play an important role in assembly and testing, ensuring accurate component connections and reliable test results.

In addition, metal V-clamp fasteners are often designed with ease of use and safety in mind. It may be equipped with an easy-to-operate adjustment mechanism to adjust the amount of clamping force according to actual needs. At the same time, in order to ensure the safety of operation, the structure and materials of the fixture may also be specially treated to prevent sliding, falling off or other safety hazards during use.

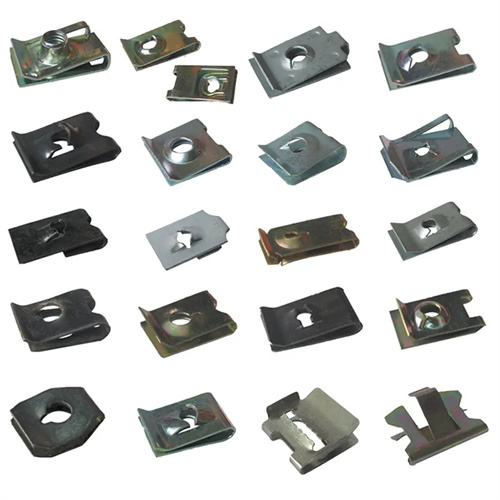

It should be noted that when selecting and using metal V-clip fasteners, it is necessary to determine the appropriate specifications and models according to the specific application scenarios and needs. For example, factors such as the shape, size and weight of the object to be clamped, as well as the magnitude and precision of the clamping force required, need to be considered. In addition, it is also necessary to pay attention to the installation and maintenance of the fixture to ensure its long-term stable operation.

As a leading manufacturer in the metal fastening industry, we take great pride in our specialization in producing Metal V Shape Flat Spring Fasteners. With a steadfast commitment to quality, innovation, and customer satisfaction, we have established ourselves as a trusted partner for businesses across diverse sectors, from automotive and aerospace to electronics and consumer goods.

Metal V Shape Flat Spring Fasteners, though seemingly simple in design, play a crucial and versatile role in countless applications. These fasteners are the unsung heroes that ensure the stability, functionality, and safety of various products and structures. Whether it’s securing components in a high – performance engine, holding parts together in a delicate electronic device, or providing reliable fastening in industrial machinery, the performance of our V Shape Flat Spring Fasteners is essential. However, creating fasteners that meet the rigorous demands of modern industries is no small feat. Traditional manufacturing methods often struggle to achieve the precision, durability, and consistency required, which can lead to product failures and costly downtime. Understanding these challenges, we have invested heavily in state – of – the – art technology and continuous research and development to revolutionize the production of our fasteners.

Our production process begins with the careful selection of premium – grade raw materials. We source only the highest quality metals, such as stainless steel, carbon steel, and aluminum alloys, known for their excellent mechanical properties, including high tensile strength, superior elasticity, and corrosion resistance. Each batch of materials undergoes rigorous testing to ensure it meets our strict quality standards before it enters the production line. This meticulous material selection process forms the foundation of our fasteners’ reliability and performance.

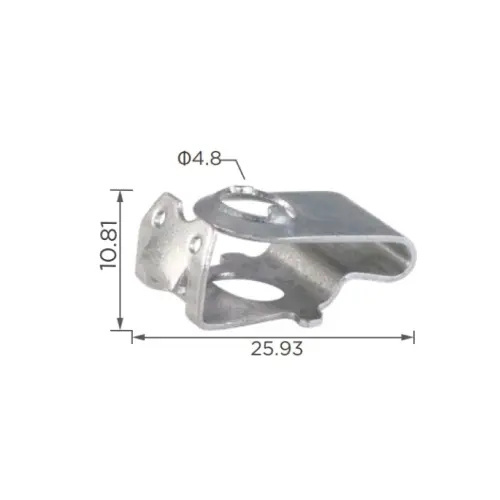

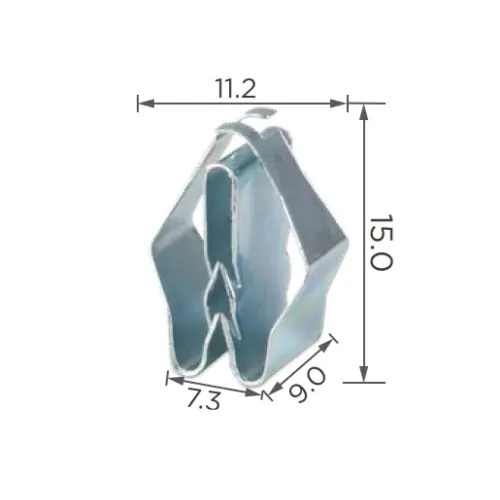

Once the materials are approved, we utilize advanced manufacturing techniques to transform them into our precision – engineered V Shape Flat Spring Fasteners. Our state – of – the – art stamping and forming equipment, controlled by sophisticated computer – aided systems, allows us to achieve unparalleled accuracy in every aspect of production. The angle of the V – shape, the thickness of the flat spring, and the overall dimensions are all carefully calibrated to ensure a perfect fit and optimal functionality. We can produce fasteners in a wide range of sizes and specifications to meet the specific needs of our customers, whether they require a small, lightweight fastener for a consumer product or a heavy – duty version for industrial applications.

Quality control is at the heart of our manufacturing operations. We have implemented a comprehensive quality management system that encompasses every stage of the production process, from raw material inspection to final product testing. In – process inspections are carried out at multiple intervals to monitor the quality of the fasteners in real – time, and any deviations from our strict standards are immediately corrected. After production, each fastener undergoes a series of rigorous tests, including tensile strength tests to measure its holding power, fatigue tests to simulate long – term usage, and dimensional inspections to ensure precision. Only fasteners that pass these exhaustive tests are approved for shipment to our customers.

What sets us apart is not only our commitment to quality but also our ability to provide customized solutions. We understand that one size does not fit all, and our team of experienced engineers and designers works closely with customers to develop Metal V Shape Flat Spring Fasteners tailored to their specific requirements. Whether it’s a unique shape, a special surface treatment, or a specific performance characteristic, we have the expertise and capabilities to bring our customers’ visions to life.

Over the years, our Metal V Shape Flat Spring Fasteners have earned a reputation for their outstanding quality, reliability, and performance. They have been trusted by leading companies around the world to meet their fastening needs. As we look to the future, we remain dedicated to continuous improvement, innovation, and customer satisfaction. We will continue to invest in new technologies, refine our manufacturing processes, and expand our product offerings to better serve our customers and stay at the forefront of the metal fastening industry.