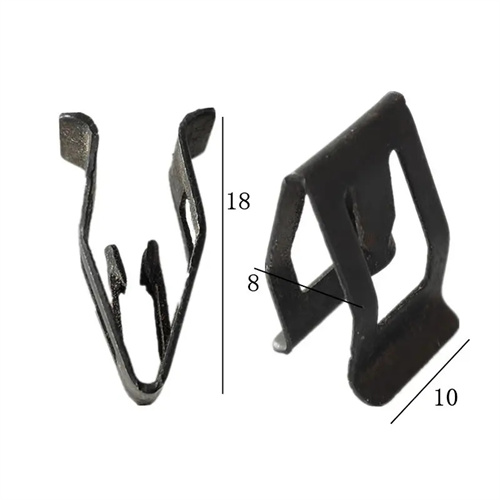

A U Clip Fasteners double-button spring U clip fasteners may refer to a spring device with two buttons, which is usually used to achieve some specific function or operation. This type of spring design allows the two buttons to trigger corresponding actions when pressed, such as electrical connections, mechanical movements, etc.

Specific to the working principle of double-button springs U clip fasteners , it may involve processes such as compression, release and return of the spring. When a button is pressed, the spring is compressed, allowing the button to establish an effective connection to the corresponding trigger (e.g. contact) for a specific function. When the button is released, the spring returns to its original shape, returning the button to its initial position.

Double-button spring U clip fasteners are available in a wide range of applications and can be customized and designed according to specific needs. For example, in electronic equipment, two-button springs can be used to achieve complex operating logic or control functions, in mechanical equipment, it can be used to control the movement of switches, valves and other components, and in household items, two-button springs can also be seen, such as switches or adjustment devices for some furniture.

The Double Button Spring Clips feature:

Robust gripping: the double button design increases the stability and strength of the gripping, enabling more secure gripping of objects.

Easy operation: the clamp can be easily opened and closed by pressing the button, which is convenient and fast to use.

Durable elasticity: high quality spring ensures good elasticity after long-time use and is not easy to loosen.

Operation convenience: switch operation is realized by pressing two buttons, which is simple, intuitive and easy to operate.

High reliability: the spring design can provide stable restoring force, ensure the accurate rebound of the button after pressing, and reduce the possibility of operation error and failure.

As a leading force in the metal fasteners manufacturing industry, we take immense pride in our expertise in crafting Metal U Clip Fasteners and Double Button Spring Clips. Our unwavering commitment to precision engineering, innovative production techniques, and stringent quality control allows us to deliver products that meet and exceed the diverse needs of our customers across multiple sectors.

Metal U Clip Fasteners and Double Button Spring Clips, though seemingly modest in size, play a crucial and versatile role in countless applications. From securing components in automotive assemblies and electronic devices to fastening parts in industrial machinery and household appliances, these clips are the unsung heroes that ensure structural integrity, stability, and seamless functionality. However, the manufacturing of high – quality clips is fraught with challenges. Traditional methods often struggle to achieve consistent precision, reliable spring force, and durability, leading to potential product failures and inefficiencies. Understanding these pain points, we have dedicated ourselves to leveraging advanced technologies and refined processes to overcome these obstacles.

When it comes to the production of our Metal U Clip Fasteners, we start with the selection of top – tier metal materials. Premium – grade stainless steel, carbon steel, and aluminum alloys are carefully sourced, chosen for their exceptional strength, corrosion resistance, and mechanical properties. Our state – of – the – art stamping and forming equipment, guided by sophisticated computer – controlled systems, enables us to shape the metal into the characteristic U – form with unparalleled accuracy. Every dimension, from the curvature of the U – arms to the thickness of the metal, is meticulously calibrated to ensure a snug fit and a secure hold, capable of withstanding vibrations, pressure, and other external forces.

Our Double Button Spring Clips, on the other hand, are a testament to our innovative design and engineering prowess. The unique double – button mechanism is a key feature that sets our clips apart. Through a combination of precision machining and advanced spring manufacturing techniques, we create clips that offer adjustable and reliable clamping force. The dual – button system allows for easy installation and removal while maintaining a firm grip on the fastened components. During production, we pay meticulous attention to the tension and resilience of the springs, ensuring that they retain their elasticity over extended periods of use, even under repeated stress.

Quality control is at the heart of our manufacturing operations. We have established a comprehensive quality management system that encompasses every stage of the production process. Raw materials undergo rigorous testing for chemical composition and mechanical properties before they are approved for use. In – process inspections are carried out at multiple intervals to monitor the quality of the clips in real – time, with any deviations immediately corrected. After production, each clip is subjected to a battery of tests. Tensile strength tests measure the clamping force, fatigue tests simulate long – term usage conditions, and dimensional inspections verify adherence to strict specifications. Only clips that pass these exhaustive tests are packaged and shipped to our customers.

Moreover, we understand that one size does not fit all. That’s why we offer a wide range of standard products as well as customized solutions. Our team of experienced engineers and designers work closely with customers to understand their specific requirements, whether it’s a unique size, shape, or functionality. We use advanced CAD/CAM systems to develop prototypes and ensure that the final products meet the exact needs of our clients.

Over the years, our Metal U Clip Fasteners and Double Button Spring Clips have gained widespread recognition and trust in the market. They have been successfully deployed in industries ranging from automotive and aerospace to electronics and construction. Looking ahead, we remain committed to continuous innovation, process optimization, and customer satisfaction. We will keep exploring new materials, refining our manufacturing techniques, and expanding our product offerings to provide even more reliable, efficient, and versatile metal fasteners for the ever – evolving needs of our customers.