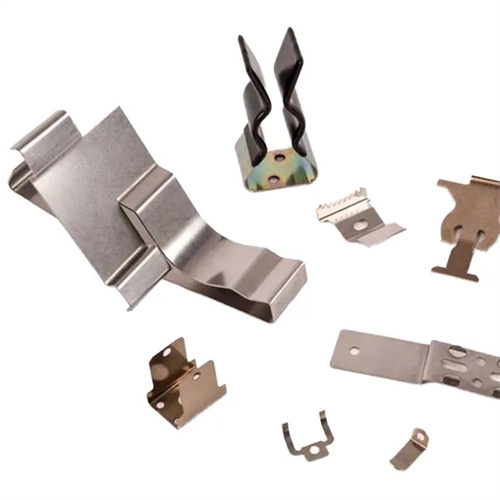

The Hole Tube Lock U V Clip Fasteners is a metal fastener used to secure or connect components such as pipes, fittings, etc. They are typically made from high quality steel (e.g., 65Mn spring steel) and are characterized by high strength, corrosion resistance, wear resistance, etc. Through their unique U-shaped or V-shaped design, these clamping elements can be tightly locked on the pipe or fitting to ensure the stability and tightness of the connection.

Product features:

High strength: Manufactured from high quality steel to withstand high tensile and pressure.

Corrosion resistance: the surface is specially treated (e.g. galvanized, nickel plated, etc.) and has good corrosion resistance.

Easy installation: reasonable design, easy and fast installation, no need for complex tools and equipment.

Good tightness: it can be tightly locked on the pipe or pipe fitting to prevent liquid or gas leakage.

Strong adaptability: applicable to the connection of pipes and pipe fittings of different diameters and materials.

Field of application:

These clamping parts are widely used in automobile, machinery, chemical industry, petroleum, natural gas, building and other fields, especially in the pipeline system that needs to withstand high pressure, high temperature or corrosive media, and are indispensable and important components.

V-shaped shrapnel is a common metal elastic element, usually made of high elastic materials such as stainless steel and nickel alloy. It has a U-shaped cross-section and can provide greater elasticity and resilience, so it is widely used in various situations that require shock absorption, cushioning, and sealing.

The working principle of U-shaped shrapnel is to absorb energy or provide sealing by bending and restoring deformation. When external forces act on U-shaped shrapnel, it undergoes bending deformation, absorbs energy, and reduces impact. When the external force disappears, the V-shaped shrapnel will return to its original state and regain its elastic effect.

The characteristics of metal U-shaped shrapnel include:

High elasticity: Metal V-shaped shrapnel has good elasticity and recovery performance, which can provide greater elasticity and recovery force.

Corrosion resistance: U-shaped shrapnel is usually made of corrosion-resistant materials such as stainless steel and nickel alloy, which can adapt to various harsh environments.

Easy to install: The U-shaped shrapnel has a simple structure and is easy to install and maintain.

Long lifespan: Due to the strong durability and fatigue resistance of v-shaped shrapnel materials, their service life is longer.

The application range of U-shaped shrapnel is very wide, including but not limited to the following areas:

Shock absorber: used to reduce the vibration and impact of mechanical equipment.

Sealing element: used to seal containers, pipelines, etc., to prevent gas or liquid leakage.

Connector: used to connect two objects or components, providing cushioning and shock absorption.

Spring: used to provide elasticity and restoring force, such as in seats, doors, and other items to play a returning role.

As seasoned professionals in the metal fastening solutions industry, we are dedicated to the design and production of Hole Tube Lock Spring Metal U V Clip Fasteners. Our unwavering focus on precision engineering, innovative manufacturing techniques, and stringent quality control allows us to deliver products that set the standard for reliability and performance across diverse applications.

Hole Tube Lock Spring Metal U V Clip Fasteners may seem like small components, but they play a crucial and multifaceted role in various industrial and consumer products. Whether it’s securing tubes and pipes in automotive exhaust systems, fastening components in machinery, or organizing cables in electronic devices, these clip fasteners are essential for maintaining structural integrity and ensuring seamless operation. However, traditional fastening methods often struggle with issues such as inconsistent clamping force, poor resistance to vibration, and limited adaptability to different tube sizes and shapes. Understanding these pain points, we’ve invested heavily in research and development to create clip fasteners that overcome these challenges.

In the manufacturing process of our Hole Tube Lock Spring Metal U V Clip Fasteners, we begin with the selection of high – quality metal materials. Premium – grade stainless steel, carbon steel, and aluminum alloys are carefully sourced, offering excellent strength, corrosion resistance, and durability. Our advanced stamping and forming technologies are then employed to shape the metal into the distinctive U and V profiles. The integration of the hole tube lock spring mechanism is a key feature of our design. Through precise machining and assembly processes, we ensure that the spring – loaded locking elements within the clips provide a secure and adjustable grip.

Our state – of – the – art computer – controlled machinery enables us to achieve micron – level precision in every aspect of production. The curvature of the clip arms, the positioning of the locking holes, and the tension of the springs are all meticulously calibrated. This level of accuracy allows our clip fasteners to fit snugly around tubes of different diameters, providing a reliable and vibration – resistant hold. For instance, in automotive applications, where engine vibrations can be intense, our clip fasteners’ spring – loaded design ensures that tubes remain firmly in place over extended periods, reducing the risk of leaks or disconnections.

Quality control is at the heart of our production philosophy. We have established a comprehensive quality management system that covers every stage of the manufacturing process. Raw materials are rigorously tested for chemical composition and mechanical properties before entering production. During the stamping and forming stages, in – line sensors continuously monitor the dimensions and shape of the clip fasteners, making real – time adjustments if necessary. After production, each clip fastener undergoes a series of rigorous tests. Tensile strength tests are conducted to measure the clamping force, fatigue tests simulate long – term usage conditions, and corrosion resistance tests expose the clips to harsh environments. Only clip fasteners that pass these extensive tests are approved for shipment.

Thanks to our commitment to excellence and our ability to provide customized solutions, our Hole Tube Lock Spring Metal U V Clip Fasteners have gained wide recognition in the market. They have been successfully applied in industries ranging from automotive and aerospace to electronics and plumbing. Looking ahead, we will continue to innovate, exploring new materials and manufacturing processes to further enhance the performance of our clip fasteners. Our goal is to not only meet but exceed our customers’ expectations, providing them with the most reliable and efficient metal fastening solutions for their unique needs.