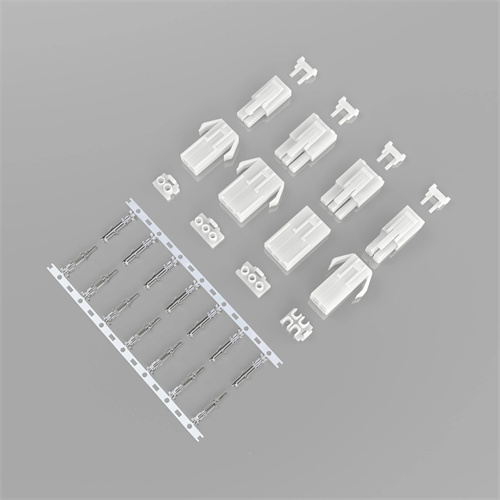

Custom Electrical Cable Lugs are electrical cable connectors designed, manufactured and manufactured to meet specific requirements. These customized cable terminals can meet the special requirements of different customers in terms of size, material, performance, shape and connection mode. The following is a detailed description of Custom Electrical Cable Lugs:

1、 Custom Advantage

Personalized design: Custom Electrical Cable Lugs can be customized according to the specific needs of customers, including size, shape, connection mode, etc. to meet specific application scenarios.

High-quality materials: high-quality copper, aluminum and their alloys can be selected as the manufacturing materials for cable terminals to ensure the conductivity, corrosion resistance and mechanical strength of the product.

Strict quality control: customized production is usually accompanied by strict quality control procedures, including raw material inspection, production process monitoring and finished product inspection, to ensure that the quality and performance of the product meet the requirements.

2、 Customized process

Demand analysis: communicate with customers to understand their specific demands and application scenarios, including cable specifications, types of connecting equipment, working environment, etc.

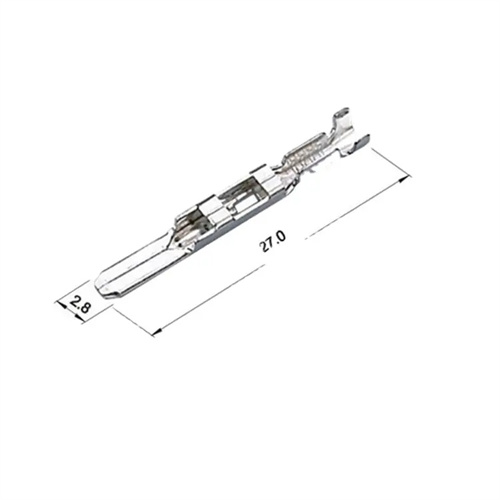

Design scheme: according to the results of demand analysis, design the preliminary scheme of cable terminal, including size, shape, connection mode, etc., and confirm with the customer.

Sample preparation: prepare samples according to the design scheme, test and verify to ensure that they meet the customer’s needs and expected performance.

Batch production: After the samples are approved by the customer, batch production shall be carried out, and production and inspection shall be carried out in strict accordance with the quality control process.

Terminal connectors have many advantages, but also have some potential drawbacks.

Advantages:

Convenient and fast: Using terminal connectors can save the steps of stripping and twisting wires, and installation and disassembly are very convenient, which greatly saves time and energy and improves work efficiency.

Stable and reliable: Terminal connectors can accommodate different cross-sectional sizes of wires, ensuring secure and stable connections. Its design often considers the effects of vibration and shock, so under certain conditions, even in the presence of vibration or shock, the wire can maintain a stable connection with the terminal.

Large wiring capacity: It can adapt to various wiring requirements and meet different application scenarios.

Easy to maintain: Due to its reusable nature, it can be easily disconnected and reconnected when repairing or replacing wires, reducing maintenance costs.

However, it also has some drawbacks:

Possible loosening under vibration or impact: Although the design of terminal connectors considers the effects of vibration and impact, under certain extreme conditions, such as strong vibration or impact, wires may loosen from the terminals, which may lead to electrical connection failure. Therefore, sufficient testing should be conducted before use to ensure the stability of its connection.

Space issue: Due to the structural characteristics of terminal connectors, their size may be limited, which may become a problem in some limited space application scenarios. When selecting terminal connectors, it is necessary to consider the size of the installation space.

Overall, terminal connectors have significant advantages in electrical connections, but their potential drawbacks also need to be considered, especially in specific application environments. Therefore, when selecting and using terminal connectors, it is necessary to weigh and choose according to specific application requirements and conditions.

As a team of experts deeply immersed in the electrical connectivity industry, we take pride in our specialization in crafting Custom Electrical Cable Lugs and Copper Terminal Connectors. Understanding that one – size – fits – all solutions rarely meet the diverse and complex requirements of modern electrical systems, we are dedicated to delivering tailor – made products that ensure optimal performance, reliability, and safety across a wide range of applications.

In today’s rapidly evolving technological landscape, electrical systems in sectors such as automotive, aerospace, renewable energy, and industrial automation demand connectors that can adapt to unique specifications. Custom Electrical Cable Lugs and Copper Terminal Connectors are not just components; they are the key to establishing seamless electrical connections, facilitating efficient power transmission, and safeguarding the integrity of entire systems. However, creating such specialized connectors presents numerous challenges, from meeting exacting dimensional requirements to ensuring superior electrical conductivity and mechanical strength. At our company, we embrace these challenges head – on with our expertise, advanced technology, and unwavering commitment to quality.

Our custom – manufacturing process begins with in – depth consultations with our clients. We work closely with engineers, designers, and project managers to thoroughly understand their specific needs, whether it’s a unique shape to fit into a confined space, a particular plating requirement for enhanced corrosion resistance, or specialized electrical and mechanical performance criteria. Once we have a clear understanding of the project requirements, our team of experienced designers utilizes advanced CAD/CAM software to create detailed 3D models of the custom connectors. This allows us to visualize the design, make necessary adjustments, and ensure that the final product will perfectly match the client’s expectations.

When it comes to material selection, we never compromise. For our Custom Electrical Cable Lugs and Copper Terminal Connectors, we source only the highest – grade electrolytic copper, known for its excellent electrical conductivity, malleability, and durability. Depending on the application, we can also incorporate other materials or alloys to enhance specific properties, such as adding tin or silver plating for improved conductivity and corrosion resistance. Each batch of raw material undergoes rigorous testing to ensure it meets our strict quality standards before entering the production line.

Our state – of – the – art manufacturing facilities are equipped with advanced machinery, including automated stamping, forging, and machining equipment, all controlled by precise computer – aided systems. This enables us to transform the raw materials into custom connectors with unparalleled accuracy and consistency. Whether it’s a complex multi – terminal connector with intricate geometries or a large – scale cable lug for high – voltage applications, our manufacturing processes are designed to meet the most demanding specifications. We pay meticulous attention to every detail, from the curvature of the lugs to the thickness of the terminal walls, ensuring a perfect fit and reliable connection.

Quality control is the cornerstone of our custom – manufacturing operations. We have implemented a comprehensive quality management system that monitors every stage of production, from raw material inspection to the final product assembly. In – process inspections are carried out at multiple intervals to check for dimensional accuracy, surface finish, and the integrity of the manufacturing process. After production, each custom connector undergoes a series of rigorous tests, including electrical conductivity tests, mechanical strength tests, and environmental simulations. We leave nothing to chance, ensuring that every Custom Electrical Cable Lug and Copper Terminal Connector we produce meets or exceeds industry standards and our clients’ specific requirements.

Over the years, our custom – made connectors have been trusted by numerous leading companies to solve their most challenging electrical connection problems. From small – scale projects to large – scale industrial installations, our products have proven their reliability and performance in the field. As we look to the future, we remain committed to innovation, continuous improvement, and customer satisfaction. We will keep investing in new technologies, expanding our capabilities, and refining our processes to provide even more advanced and tailored Custom Electrical Cable Lugs and Copper Terminal Connectors, helping our clients stay ahead in the ever – evolving electrical industry.