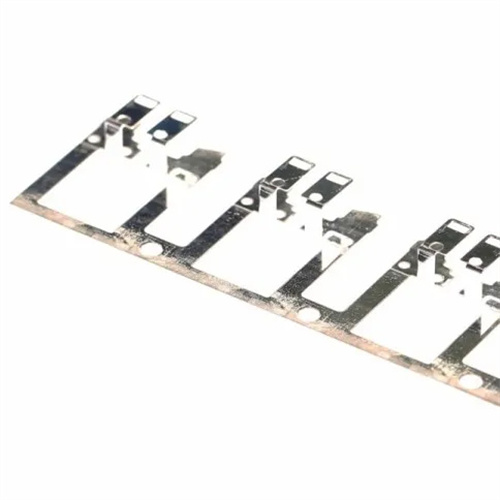

Copper battery cable lugs battery cable terminal connectors

There are various materials for terminal connectors, each with its unique characteristics and applicable scenarios. Here are some common materials:

1. Metal: Metal materials such as copper, aluminum, etc. are the main materials used to make terminal connectors. They have robustness and good conductivity, making them suitable for various harsh working environments. Copper terminal connectors are highly favored due to their excellent conductivity, long service life, and ability to resist certain corrosion. Aluminum terminal connectors have cost advantages and also have good conductivity and corrosion resistance.

2. Copper alloys: such as thin-walled copper pipes, copper nickel, and copper oxide. These materials not only have good conductivity and welding performance, but are also suitable for high temperature, high pressure, and high frequency electronic devices.

3. Engineering plastics: such as nylon, polyester, and polypropylene. These plastic materials perform excellently in low pressure, low temperature, and general electronic devices due to their excellent mechanical properties, corrosion resistance, and insulation properties.

4. Stainless steel: Stainless steel terminal connectors have the characteristics of corrosion resistance, good toughness, and high strength, but their processing difficulty and cost are relatively high.

In addition, there are tin terminal connectors that perform well in specific applications such as automotive parts and electronic components due to their excellent oxidation resistance, corrosion resistance, and high temperature resistance.

Copper Battery Cable Lugs has the following features and advantages:

Good conductivity: copper has excellent conductivity, which can ensure the efficient transmission of current between the battery and the cable and reduce energy loss.

Corrosion resistance: good resistance to oxidation and corrosion, stable performance under various environmental conditions, and extended service life.

Good thermal conductivity: help to dissipate the heat generated during the operation of the battery, reduce the risk of overheating, and improve the safety and stability of the battery system.

High-strength connection: it can provide firm and reliable connection, ensure close connection between cable and battery pole, and not easy to loosen.

In actual application:

For example, in the battery system of the vehicle, the copper battery cable terminal can ensure the stable supply of power and support the normal start of the vehicle and the operation of electronic equipment. In industrial energy storage system, they can provide safe and reliable connection for large battery pack.

As dedicated professionals in the electrical connectivity solutions industry, we take immense pride in our expertise in manufacturing Copper Battery Cable Lugs and Battery Cable Terminal Connectors. With a profound understanding of the critical role these components play in ensuring efficient power transmission and system reliability, we are committed to delivering products that meet the highest standards of quality, performance, and durability.

Copper Battery Cable Lugs and Battery Cable Terminal Connectors are the unsung heroes of electrical systems, especially in battery – powered applications ranging from automotive and marine to renewable energy storage and industrial machinery. These connectors serve as the vital link between battery cables and various electrical components, facilitating the seamless flow of electrical current. However, the manufacturing of top – tier copper connectors is fraught with challenges. The need for excellent electrical conductivity, robust mechanical strength, and resistance to corrosion and environmental factors requires precision engineering and advanced manufacturing techniques. Recognizing these demands, we have invested heavily in research, cutting – edge technology, and a skilled workforce to produce connectors that excel in every aspect.

Our production process for Copper Battery Cable Lugs and Terminal Connectors commences with the selection of premium – grade copper. We source high – purity electrolytic copper, renowned for its exceptional electrical conductivity and malleability. This raw material forms the foundation of our products, ensuring minimal electrical resistance and maximum power transfer efficiency. Before entering the production line, each batch of copper undergoes rigorous testing for chemical composition, electrical properties, and mechanical strength to guarantee compliance with our stringent quality criteria.

Once the copper is approved, we employ advanced manufacturing methods to shape it into our precision – engineered connectors. For our cable lugs, we utilize state – of – the – art cold – pressing and forging techniques. These processes enhance the mechanical integrity of the lugs, creating a secure and permanent connection when crimped onto battery cables. The internal structure of the lugs is carefully designed to provide a large contact area with the cable, minimizing the risk of overheating and ensuring a stable electrical connection. Our Battery Cable Terminal Connectors, on the other hand, are crafted with equal precision. Whether it’s a simple ring – type connector or a more complex multi – terminal design, we use computer – controlled machining and stamping equipment to achieve consistent dimensions and a perfect fit for various cable sizes and connection requirements.

Quality control is at the core of our manufacturing philosophy. We have established a comprehensive quality management system that monitors every stage of production. In – process inspections are carried out to check for dimensional accuracy, surface finish, and the integrity of the manufacturing process. After production, each connector undergoes a series of rigorous tests. Electrical conductivity tests are performed to ensure that the connectors meet or exceed industry standards for power transfer. Mechanical strength tests, such as pull – out and torque tests, verify the durability of the connection. Additionally, we subject our connectors to salt spray and humidity tests to assess their corrosion resistance, ensuring they can withstand harsh environmental conditions. Only connectors that pass these exhaustive tests are approved for shipment to our customers.

In addition to our standard product range, we also offer customized solutions. Our team of experienced engineers works closely with customers to understand their unique requirements, whether it’s a specific size, shape, or additional features. Using advanced CAD/CAM technologies, we can design and produce tailor – made Copper Battery Cable Lugs and Terminal Connectors to meet the exact needs of any application.

Over the years, our Copper Battery Cable Lugs and Battery Cable Terminal Connectors have earned a reputation for their outstanding quality and reliability, and have been trusted by leading companies in various industries worldwide. As the demand for efficient and reliable electrical connectivity solutions continues to grow, we remain committed to innovation, continuous improvement, and customer satisfaction. We will keep exploring new materials, refining our manufacturing processes, and expanding our product offerings to provide even more advanced and dependable connectors for the evolving needs of our customers.