Choosing the appropriate connector is a process that requires considering multiple factors.

1. Application requirements: Firstly, you need to clarify the usage scenarios and requirements of the terminal connector. For example, the number of signals you need to connect, current rating, working voltage, working environment, etc. These factors will directly affect the terminal connector type, specifications, and performance you choose.

2. Environmental conditions: Consider the environmental conditions in which the connector will operate, such as temperature, humidity, salt spray, vibration, and impact. These environmental factors can affect the stability and reliability of terminal connector , so you need to choose a terminal connector that can work properly under these conditions.

3. Physical characteristics and electrical performance: Pay attention to the physical characteristics and electrical performance of the connector, such as the number of pins, pin spacing, maximum current, contact resistance, insulation resistance, and electrical strength. These characteristics will directly affect the transmission efficiency and stability of the terminal connector .

4. Reliability: The reliability of terminal connector is crucial, especially in critical application scenarios. Choose connectors with excellent stability and durability to reduce the likelihood of malfunctions and repairs.

5. Easy installation and maintenance: Consider the convenience of terminal connector installation and maintenance. Choosing connectors that are easy to install and disassemble can save time and labor costs. At the same time, consider the interchangeability and standardization of connectors for future maintenance and upgrades.

6. Cost effectiveness: Consider the cost-effectiveness of connectors while meeting application requirements. Choosing terminal connector with high cost-effectiveness can help reduce overall project costs.

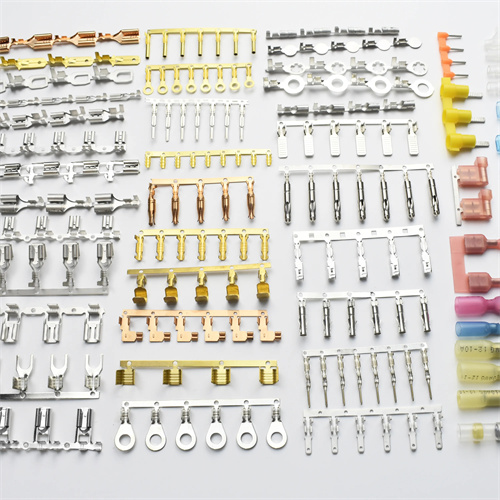

Electrical Cable Lugs is an important component used for connection between cables and equipment or between cables in electrical connection. They are usually made of conductive materials, such as copper, aluminum, or copper-aluminum alloys, and are subjected to specific processes, such as tin plating, crimping, etc., to ensure good conductivity and bond strength. The following is a detailed description of Electrical Cable Lugs:

Electrical Cable Lugs can be divided into pure copper cable lugs and copper-aluminum alloy cable lugs according to different materials. The pure copper cable lug has good conductivity and corrosion resistance, while the copper-aluminum alloy cable lug combines the advantages of copper and aluminum, with better comprehensive performance. In addition, special materials such as stainless steel cable lugs are available for electrical connections in specific environments.

Electrical Cable Lugs usually consists of the following parts:

Conductor part: connected with cable conductor to ensure smooth current flow.

Crimping part: the crimping process is closely combined with the cable conductor to form a reliable electrical connection.

Insulated part (part of product): for the occasion requiring insulation, the cable connection nose will be designed with insulation layer to prevent electrical leakage and short circuit.

Electrical Cable Lugs features include:

Good conductivity: made of high-quality conductive materials to ensure current transmission efficiency.

Reliable connection: close connection with cable conductor through crimping and other processes to form stable electrical connection.

Strong corrosion resistance: after special treatment, it has good corrosion resistance and is applicable to various harsh environments.

Easy installation: reasonable design, easy and fast installation, and improved work efficiency

As a dedicated factory specializing in electrical connectivity solutions, we take immense pride in our role as manufacturers of Electrical Cable Lugs and Copper Terminal Connectors. With a deep – seated commitment to quality, innovation, and customer satisfaction, we have established ourselves as a trusted partner for industries worldwide, ensuring seamless power transmission and reliable electrical connections.

Electrical Cable Lugs and Copper Terminal Connectors are the unsung heroes of electrical systems, serving as the critical link between cables and various electrical components. Whether in power distribution networks, automotive applications, industrial machinery, or renewable energy setups, these connectors play a pivotal role in facilitating the efficient flow of electrical current. The performance of these components directly impacts the safety, reliability, and longevity of electrical systems. Recognizing the high – stakes nature of our products, we have spared no effort in perfecting our manufacturing processes and technologies.

Our production journey commences with the meticulous selection of raw materials. For our Copper Terminal Connectors and Cable Lugs, we source only the highest – grade electrolytic copper. Renowned for its exceptional electrical conductivity, malleability, and thermal properties, this high – purity copper forms the cornerstone of our products’ reliability. Each batch of raw material undergoes rigorous testing for chemical composition, electrical resistivity, and mechanical strength before being approved for production. This stringent quality control at the source ensures that every connector and lug we produce starts with the best possible foundation.

Once the raw materials are deemed suitable, we employ state – of – the – art manufacturing techniques. Our factory is equipped with advanced automated stamping, forging, and machining equipment, all integrated with sophisticated computer – controlled systems. This enables us to achieve unparalleled precision in every aspect of production. For cable lugs, our cold – pressing and forging processes not only enhance the mechanical integrity of the lugs but also create a secure, low – resistance connection when crimped onto cables. The internal structure of our lugs is designed to maximize the contact area with the cable, minimizing the risk of overheating and ensuring a stable electrical connection under heavy loads.

Similarly, our Copper Terminal Connectors are crafted with meticulous attention to detail. Whether it’s a simple ring – type connector for basic electrical setups or a complex multi – terminal design for high – end applications, we can produce connectors in a wide range of sizes and specifications. Our machining and stamping processes ensure consistent dimensions, precise shapes, and smooth surfaces, which are essential for easy installation and reliable performance.

Quality control is ingrained in every step of our manufacturing process. We have implemented a comprehensive, multi – stage quality assurance program. In – process inspections are carried out continuously to monitor dimensions, surface finish, and the integrity of the manufacturing operations. After production, each Electrical Cable Lug and Copper Terminal Connector undergoes a battery of rigorous tests. Electrical conductivity tests are performed to verify optimal current transfer capabilities, while mechanical tests, such as pull – out and torque tests, assess the strength and durability of the connection. Additionally, we subject our products to environmental tests, including salt spray and humidity resistance trials, to ensure they can withstand harsh operating conditions. Only products that pass these exhaustive tests are cleared for shipment to our customers.

In addition to our standard product range, we also offer customized solutions. Our team of experienced engineers works closely with clients to understand their unique requirements, whether it’s a specific shape, size, plating finish, or enhanced electrical and mechanical properties. Using advanced CAD/CAM technologies, we can develop prototypes and produce tailor – made connectors and lugs that precisely meet the demands of any electrical project.

Over the years, our Electrical Cable Lugs and Copper Terminal Connectors have earned a reputation for their outstanding quality, reliability, and performance. Trusted by leading companies across diverse industries, we are committed to continuous improvement. We will keep investing in research and development, exploring new materials and manufacturing techniques, and expanding our product offerings to meet the evolving needs of the electrical connectivity market. Our goal is to remain at the forefront of the industry, providing the most advanced and dependable solutions for our customers’ electrical connection needs.