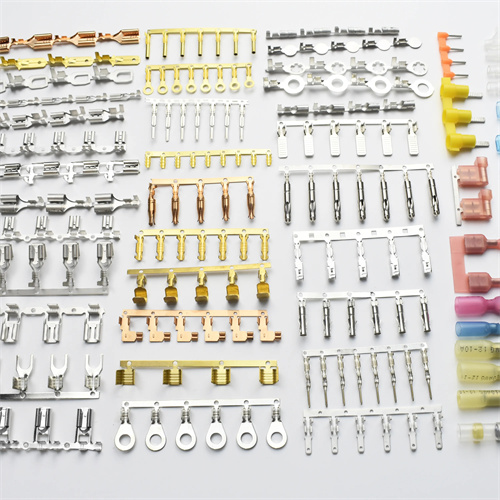

Unrivaled Capabilities in Custom Terminal Connector Design

As providers of custom terminal connector solutions, we take pride in our unrivaled capabilities that span from the initial design concept all the way to mass production. Our expertise lies in understanding the unique requirements of each client, whether it’s for a specialized application in the aerospace industry or a novel consumer electronics product. We combine in – depth knowledge of electrical engineering, material science, and manufacturing processes to offer tailored solutions for Terminal Connectors.

Our team of experienced designers and engineers uses advanced software tools to create innovative connector designs. We can optimize for factors such as electrical conductivity, mechanical strength, size constraints, and environmental resistance. This comprehensive approach ensures that our custom Terminal Connectors not only meet but exceed client expectations, providing a competitive edge in the market.

Collaborative Design Process for Terminal Connectors

Our design process for custom Terminal Connectors is highly collaborative. We start by engaging in detailed discussions with our clients to understand their specific needs, including electrical load requirements, operating environment, and mechanical constraints. Through site visits, technical reviews, and brainstorming sessions, we gather all the necessary information to create a design brief.

Using CAD (Computer – Aided Design) software, we develop initial design concepts that incorporate the client’s specifications. These concepts are then presented to the client for feedback. We iterate on the designs based on client input, making adjustments to ensure the Terminal Connectors are perfectly suited to their intended application. This collaborative approach not only results in a better – designed product but also builds a strong partnership with our clients throughout the project.

Efficient Prototyping Services for Terminal Connectors

Once the design is finalized, we move on to the prototyping stage for our custom Terminal Connectors. Our efficient prototyping services allow clients to test and validate the design before committing to mass production. We use a variety of rapid prototyping techniques, such as 3D printing, CNC machining, and injection molding, depending on the complexity and material requirements of the connectors.

These prototypes are fully functional and can be used for electrical testing, mechanical stress testing, and fit – and – form evaluation. We work closely with clients during this stage, providing them with detailed reports on the prototype’s performance and making any necessary design refinements. Our goal is to ensure that the final product meets all the required specifications and performs flawlessly in real – world applications.

Seamless Transition to Mass Production of Terminal Connectors

After the prototype has been approved, we facilitate a seamless transition to mass production of our custom Terminal Connectors. Our manufacturing facilities are equipped with state – of – the – art production lines that can handle high – volume orders with precision and efficiency. We have established partnerships with reliable raw material suppliers to ensure a steady supply of high – quality materials.

Our production team carefully calibrates the manufacturing processes, from stamping and molding to assembly and quality control, to maintain consistent quality across all units. We also implement lean manufacturing principles to reduce waste and optimize production efficiency. This allows us to offer competitive pricing without compromising on the quality of our custom Terminal Connectors during mass production.

Rigorous Quality Control in Terminal Connector Production

Quality control is a top priority throughout the production of our custom Terminal Connectors. We have a comprehensive quality management system in place that monitors every aspect of the manufacturing process. From raw material inspection to the final product testing, each step is subject to strict quality checks.

Our quality control team uses advanced testing equipment to measure electrical conductivity, mechanical strength, and durability of the connectors. We conduct tests such as salt – spray testing for corrosion resistance, high – voltage testing for electrical safety, and vibration testing to simulate real – world conditions. Only Terminal Connectors that pass all these rigorous tests are approved for shipment, ensuring that our clients receive products of the highest quality.

Comprehensive Customer Support for Terminal Connectors

We are committed to providing comprehensive customer support for our custom Terminal Connector design and production services. Our support team, consisting of customer service representatives, engineers, and project managers, is available throughout the entire project lifecycle. We offer detailed consultations during the design phase, helping clients define their requirements and choose the best design options.

During prototyping and production, we keep clients informed of the progress, providing regular updates and addressing any concerns promptly. In the post – project phase, we offer after – sales support, including assistance with installation, troubleshooting, and maintenance. We also welcome feedback from clients to continuously improve our services, aiming to build long – term, mutually beneficial relationships.