The Corrosion-Resistant Principle of Gold-Plated Terminal Connectors

Our Gold-Plated Terminal Connectors owe their exceptional corrosion resistance to the unique properties of gold. Gold is a noble metal renowned for its remarkable chemical stability. It has an extremely low reactivity, which means it does not readily oxidize or corrode when exposed to air, moisture, or most common chemicals. When gold plating is applied to the surface of our Terminal Connectors, it forms a protective layer that shields the underlying base material from environmental corrosive agents.

The plating process involves depositing a thin but continuous layer of gold onto the connector surfaces. This layer acts as an impermeable barrier, preventing the ingress of substances that could cause degradation. In precision electronics, where even the slightest corrosion can disrupt the functionality of sensitive circuits, this protective layer ensures the long – term reliability and performance of our Terminal Connectors.

Superior Performance in Precision Electronics of Terminal Connectors

Our Gold-Plated Terminal Connectors deliver superior performance in precision electronics. Gold’s excellent electrical conductivity ensures efficient power transfer and signal transmission with minimal resistance. In devices such as high – end medical equipment, aerospace avionics, and advanced communication systems, where accurate and stable electrical connections are crucial, these connectors minimize power loss and signal distortion.

The smooth and consistent surface of the gold plating also reduces contact resistance at the interface between the connectors and mating components. This results in a more reliable connection, reducing the risk of intermittent electrical signals or connection failures. Additionally, the corrosion resistance of gold plating ensures that the electrical performance of the connectors remains stable over time, even in challenging operating environments, contributing to the overall reliability of precision electronic devices.

Meticulous Design and Manufacturing of Gold-Plated Terminal Connectors

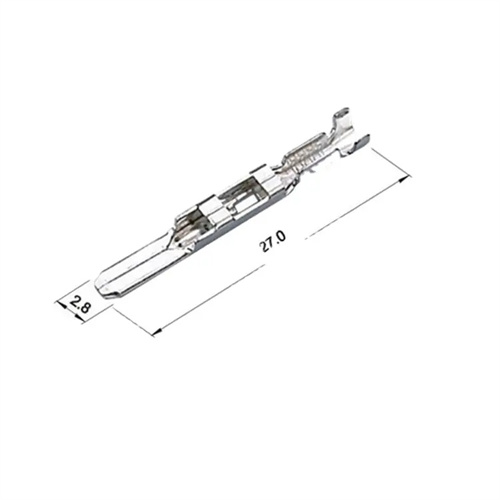

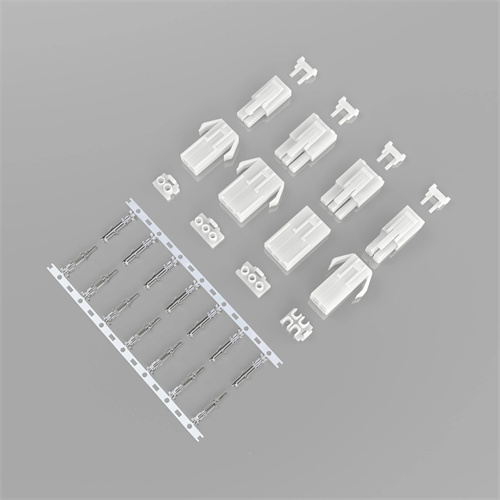

The production of our Gold-Plated Terminal Connectors involves a meticulous design and manufacturing process. We begin by selecting high – quality base materials, such as copper or its alloys, which provide excellent electrical conductivity and mechanical strength as a foundation. The design of the connectors is optimized for precision electronics, taking into account factors such as size constraints, mating requirements, and environmental conditions.

Our manufacturing facilities are equipped with advanced plating and machining equipment. The gold plating process is carefully controlled, with precise parameters for the plating solution, temperature, current density, and plating time to ensure a uniform and consistent gold layer of the desired thickness. After plating, each Terminal Connector undergoes a series of inspections, including dimensional checks, surface finish evaluations, and electrical conductivity tests, to ensure it meets our strict quality standards.

Rigorous Quality Control of Gold-Plated Terminal Connectors

Quality control is integral to our production of Gold-Plated Terminal Connectors. We have established a comprehensive quality management system that monitors every stage of the manufacturing process, from raw material procurement to the final product. Our quality control team uses advanced testing equipment to measure the thickness of the gold layer accurately, check for any surface defects, and verify the electrical performance of the connectors.

We conduct a series of reliability tests, such as salt – spray testing, humidity testing, and high – temperature testing, to simulate real – world environmental conditions and ensure the connectors’ corrosion resistance. Only Gold-Plated Terminal Connectors that pass all these rigorous quality control checks are approved for shipment, guaranteeing that our products meet the high – standards required by precision electronics manufacturers.

Diverse Applications in Precision Electronics of Terminal Connectors

Our Gold-Plated Terminal Connectors find diverse applications in precision electronics. In the medical field, they are used in diagnostic equipment, such as MRI machines, CT scanners, and electrocardiographs, where reliable electrical connections are essential for accurate test results. In the aerospace industry, these connectors are critical for avionics systems, ensuring stable communication and control in the harsh environment of flight.

For high – end consumer electronics, such as smartphones, laptops, and digital cameras, our connectors enable efficient power and data transfer. They are also widely used in the telecommunications industry for network infrastructure equipment, where their reliability and corrosion resistance contribute to the seamless operation of communication systems. From life – saving medical devices to cutting – edge consumer gadgets, our Gold-Plated Terminal Connectors play a vital role in precision electronics.

Comprehensive Customer Support for Gold-Plated Terminal Connectors

We are committed to providing comprehensive customer support for our Gold-Plated Terminal Connectors. Our team of experts, including electrical engineers, material scientists, and customer service representatives, is available to assist customers throughout the entire process, from product selection to after – sales service. We offer detailed technical advice on choosing the right type of connector for specific precision electronics applications, taking into account factors such as electrical load, operating temperature, and environmental exposure.

In case of any issues or concerns, our responsive after – sales service team is ready to provide prompt solutions. Whether it’s a question about product performance, a need for replacement parts, or assistance with installation, we strive to ensure that our customers are completely satisfied with our products and services. We also welcome feedback from our customers to continuously improve our offerings, aiming to build long – term relationships based on trust, reliability, and exceptional support in the precision electronics market.