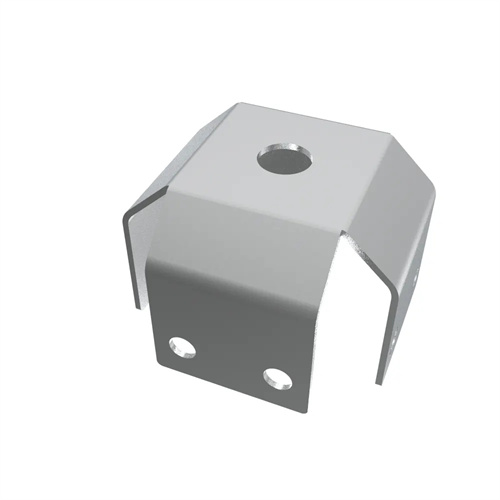

The U-Shape Metal Spring Clip features the following:

Excellent elasticity: the characteristics of the spring enable it to generate large rebound force, so as to tightly clamp the object and provide stable clamping force.

Flexibility: adaptive adjustment can be made within a certain range according to the size and shape of the clamped object, which increases its versatility.

Quick fixation: it can quickly complete the fixation and release of the object and improve the work efficiency.

Wear-resistant: The metal material usually has good wear-resistant performance and can withstand multiple use without damage.

Rust prevention: surface treatment, such as galvanization and chromium plating, can enhance rust prevention and corrosion resistance and extend the service life.

U-shaped metal spring clamp is widely used in many fields, such as:

In office supplies, it is used to fix documents and paper, so as to make the desk clean.

In family life, clothes and bags can be clamped.

In industrial production, small parts, pipes, etc. are fixed.

The U-shaped metal spring clamp is a kind of fixture that uses the mechanical principle of elastic deformation to work. It works on the principle that when an external force acts on the jaw arm, the jaw arm deforms, resulting in an elastic force that is used to clamp the object and hold it in a certain position.

U-shaped metal spring clips have a wide range of applications, including but not limited to machinery, automotive, construction, etc. In the mechanical and automotive sectors, it is often used to clamp pipes, clamp workpieces, etc., to ensure that these components maintain a stable position and prevent movement. In the construction field, the U-shaped metal spring clamp also plays an important role, for example, in the water supply, gas, heating and other systems, it is often used to fix and install pipes to avoid problems such as pipe leakage and falling off.

In addition, U-shaped metal spring clips can also be used to fix wires and cables, and bundle wires tightly to walls, roofs, or other structures to keep wires neat and secure. It can also prevent wires from loosening, entanglement, or stretching by external forces, thus preventing safety hazards such as wire aging and short circuits.

With its unique clamping method and wide range of applications, the U-shaped metal spring clamp has become an indispensable and important tool in industrial production and daily life.

As dedicated manufacturers in the metal components industry, we take great pride in our specialization as producers of U – Shape Metal Spring Clips. With years of expertise, cutting – edge technology, and an unwavering commitment to quality, we strive to deliver products that are not only reliable but also exceed the expectations of our diverse clientele across various sectors.

U – Shape Metal Spring Clips, despite their seemingly simple design, are indispensable in countless applications. From securing components in automotive engines and household appliances to organizing cables in electronic devices and holding parts together in industrial machinery, these clips play a crucial role in ensuring the stability, functionality, and safety of end – products. However, the manufacturing of high – quality U – Shape Metal Spring Clips is no easy feat. Traditional manufacturing methods often face challenges such as inconsistent precision, insufficient spring force, and limited durability, which can lead to product failures and costly downtime for our customers. Recognizing these pain points, we have continuously invested in research, development, and state – of – the – art equipment to revolutionize the production process.

Our production journey begins with the careful selection of premium – grade raw materials. We source only the finest metals, including high – strength stainless steel, corrosion – resistant aluminum alloys, and durable carbon steel, depending on the specific requirements of our customers. This meticulous material selection process guarantees that our U – Shape Metal Spring Clips possess excellent mechanical properties, such as high tensile strength, superior elasticity, and resistance to wear and tear.

Once the materials are selected, we employ advanced manufacturing techniques to shape them into the distinctive U – form. Our cutting – edge stamping and forming equipment, controlled by sophisticated computer – aided systems, enables us to achieve unparalleled precision. Every aspect of the clip, from the curvature of the U – arms to the thickness of the metal and the tension of the spring mechanism, is carefully calibrated and monitored. This level of precision ensures a perfect fit for a wide range of applications, providing a secure and reliable hold that can withstand even the most demanding conditions.

Quality control is the cornerstone of our manufacturing philosophy. We have implemented a rigorous, multi – stage quality assurance process to ensure that each U – Shape Metal Spring Clip leaving our facility meets the highest standards. From initial raw material inspection to in – process checks during production and final product testing, every clip is thoroughly examined. We use advanced measuring instruments to verify dimensions, perform tensile and fatigue tests to assess the spring force and durability, and conduct salt spray and other environmental tests to evaluate corrosion resistance. Only those clips that pass these comprehensive tests are approved for shipment to our customers.

In addition to our standard product range, we also offer customized solutions to meet the unique needs of our clients. Our team of experienced engineers and designers work closely with customers, from the initial concept stage to final production, to develop U – Shape Metal Spring Clips that are tailored to their specific requirements. Whether it’s a special size, a unique shape, or a customized spring tension, we have the capabilities and expertise to bring our customers’ visions to life.

Over the years, our U – Shape Metal Spring Clips have earned a reputation for their outstanding quality, reliability, and performance. They have been widely adopted by leading companies in various industries around the world. As we move forward, we remain committed to continuous improvement, innovation, and customer satisfaction. We will continue to invest in new technologies and processes, refine our manufacturing techniques, and expand our product offerings to better serve our customers and stay at the forefront of the metal spring clip manufacturing industry.