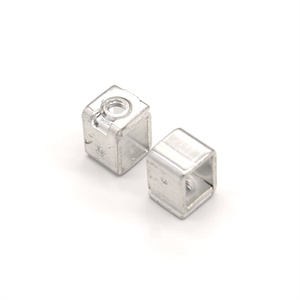

Battery Contact Plates are suitable for blackening treatment. Blackening treatment is a chemical surface treatment method that can form an oxide film on the metal surface to improve its corrosion resistance, wear resistance, and decorative properties. For components such as battery contact plates that come into direct contact with the battery, enhancing their corrosion resistance and wear resistance is crucial.

The battery contact plate plays a crucial role in the battery system, responsible for conducting current and ensuring the stable operation of the battery. However, battery systems often face various environmental conditions, such as moisture, corrosive chemicals, etc., all of which may affect the performance of battery contact plates. Through blackening treatment, a dense oxide film will form on the surface of the battery contact plate, which not only isolates harmful external factors and improves the corrosion resistance of the contact plate, but also enhances its wear resistance to a certain extent and extends its service life.

The blackening treatment of Battery Contact Plates usually does not have a significant impact on their conductivity. The oxide layer generated by blackening treatment can be regarded as a thin film, which is relatively thin and has good conductivity, so it does not significantly hinder the conduction of current.

However, if the blackening treatment is improper or inappropriate chemicals are used during the processing, it may cause damage to the surface of the Battery Contact Plates, thereby affecting their conductivity. Therefore, when carrying out blackening treatment, it is necessary to ensure correct operation and use appropriate chemicals and process parameters.

In addition, it should be noted that the battery contact plate may require further cleaning and treatment after blackening to ensure its surface is clean and free of impurities, thereby maintaining good conductivity.

Although blackening treatment usually does not have a significant impact on the conductivity of Battery Contact Plates, it is still necessary to pay attention to the correctness of operation and the integrity of subsequent processing to ensure that the performance of the battery contact plates is not affected.